At Mouldtech Industries, we take pride in being a trusted Secondary Belt Cleaner Products Manufacturer offering durable, efficient, and performance-driven solutions for bulk material handling systems. Our Secondary Belt Cleaners are engineered to deliver superior belt cleaning performance, extend conveyor belt life, and ensure seamless material flow — even

in the most demanding industrial environments. Whether it’s Mining & Metal Industries, Minerals Industries, Ceramic Industries, Cement Industries, Energy & Green Industries, or Manufacturer & Machine Parts, our belt cleaners provide unmatched reliability and long-term efficiency.

As a leading Manufacturer Of Secondary Belt Cleaner, Mouldtech Industries is dedicated to manufacturing world-class convey or cleaning equipment that ensures optimal conveyor performance. Headquartered in Vadodara, Gujarat, we specialize in designing belt cleaning systems that meet international quality standards while offering exceptional value for industries requiring clean, efficient conveyor operations. We are renowned as a Secondary Belt Cleaner Manufacturer in Vadodara and a Manufacturer Of Secondary Belt Cleaner in Gujarat, with our products widely trusted across India and globally. Our manufacturing excellence, customer-centric approach, and focus on innovation make us one of the most reliable Secondary Belt Cleaner Manufacturer and Supplier in the material handling industry.

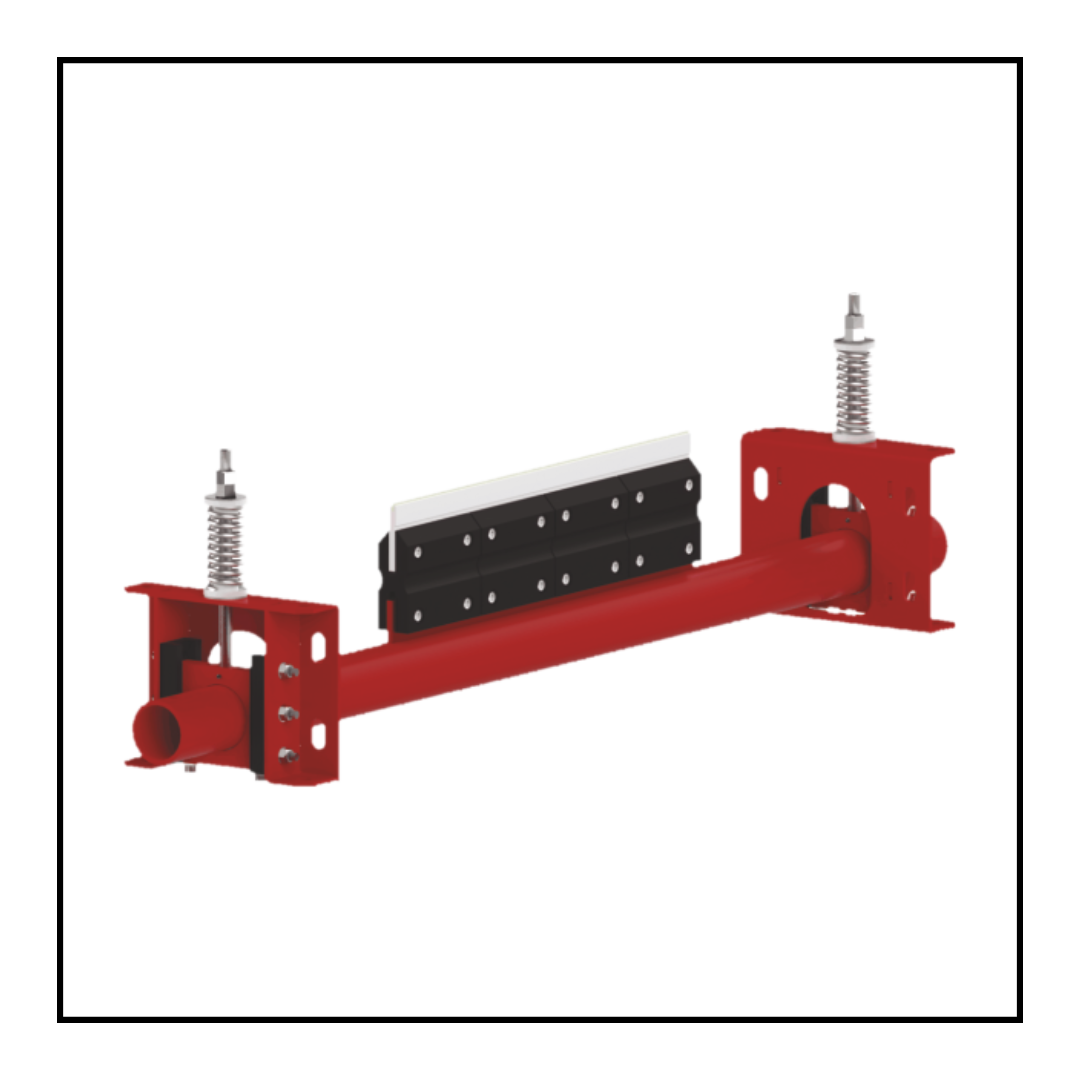

A Secondary Belt Cleaner (also known as a secondary scraper) is a critical component installed right after the primary cleaner on a conveyor system. It is designed to remove the remaining fine materials and residues left behind by the primary cleaner. This ensures that the conveyor belt surface is completely clean, reducing carryback, preventing material buildup on pulleys and idlers, and minimizing maintenance downtime. A well-designed secondary cleaner enhances system performance, improves productivity, and extends the service life of the entire conveyor system.

Our Secondary Belt Cleaner products are widely used across multiple industries that rely on conveyor systems for material handling.

When it comes to Secondary Belt Cleaners, Mouldtech Industries is the preferred choice among industrial clients for several reasons:

When you need a durable, efficient, and cost-effective solution for your conveyor system, choose Mouldtech Industries — your trusted Secondary Belt Cleaner Manufacturer and Supplier. We ensure every product delivers performance, longevity, and reliability across diverse industrial applications.

Whether you’re in Mining, Cement, Ceramic, or Energy sectors, our products will help you achieve cleaner, safer, and more productive material handling operations.

+91-9998003813

info@mouldtechindustries.in

A Secondary Belt Cleaner is installed on a conveyor system after the primary cleaner to remove any remaining material from the belt, ensuring minimal carryback and reducing spillage. Mouldtech Industries manufactures durable secondary belt cleaners for industrial applications.

It provides secondary cleaning, protecting downstream equipment, minimizing material loss, reducing maintenance, and improving overall conveyor efficiency.

They are constructed from high-quality polyurethane, rubber, and stainless steel, offering excellent abrasion resistance, durability, and reliable cleaning performance.

Yes. Mouldtech Industries designs custom secondary cleaners to suit conveyor width, belt speed, material type, and operational requirements.

By removing residual material left after the primary cleaner, it prevents spillage, reduces belt wear, and ensures smooth, uninterrupted operation of the conveyor system.

Yes. Mouldtech Industries Secondary Belt Cleaners are compatible with a wide range of industrial conveyors in mining, cement, steel, and other sectors.

WhatsApp us