Welcome to Mouldtech Industries, your trusted Lifter Bar (Radical) Products Manufacturer delivering precision-engineered mill lining solutions designed to enhance performance, reduce downtime, and extend service life. As a leading Manufacturer of Lifter Bar (Radical) Products in Vadodara and a reputed Manufacturer of Lifter Bar (Radical) Products in Gujarat, we specialize in producing durable and efficient lifter bars suitable for heavy-duty applications across various industrial sectors including Mining & Metal Industries, Minerals Industries, Ceramic Industries, Cement Industries, Energy & Green Industries, and Manufacture & Machine Parts.

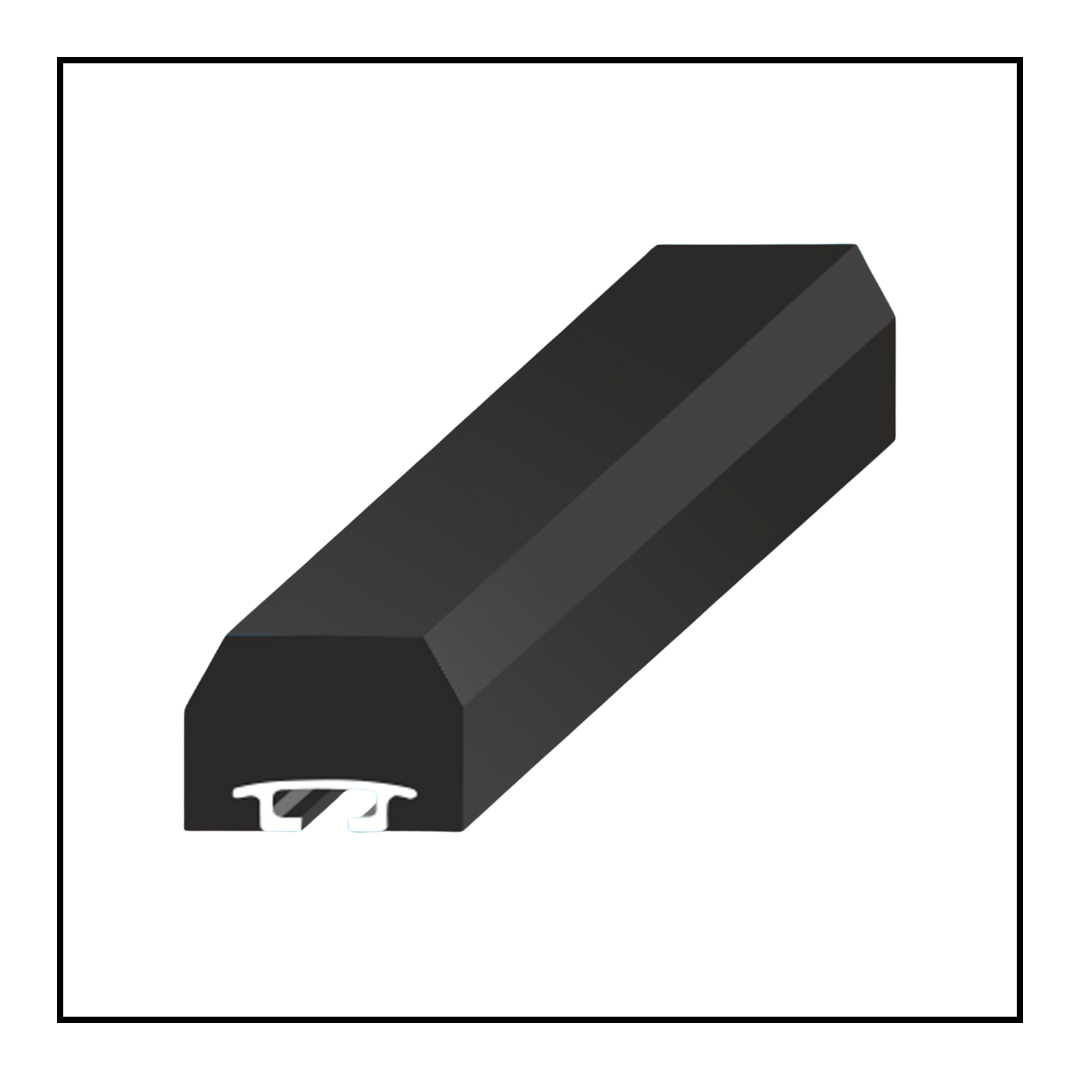

At Mouldtech Industries, we are dedicated to designing and manufacturing advanced mill lining components that ensure maximum operational efficiency. Our Lifter Bar (Radical) products are designed with high-grade rubber or composite materials that deliver excellent wear resistance, corrosion protection, and long-lasting performance under extreme conditions. With state-of-the-art production facilities and experienced engineers, Mouldtech Industries has earned its reputation as a reliable Lifter Bar (Radicial) Products Manufacturer and Supplier serving industries across India and beyond.

A Lifter Bar (Radical) is a vital component used inside ball mills and other grinding machines to lift the charge (grinding media and material) during rotation. Its radial design optimizes energy transfer and promotes effective grinding, resulting in enhanced mill performance and reduced energy consumption. By integrating Lifter Bar (Radicial) systems into your mills, you can ensure:

Efficient material movement

Reduced wear on mill shells

Improved grinding efficiency

Lower maintenance costs

At Mouldtech Industries, every Lifter Bar (Radical) is manufactured using advanced

techniques and premium-grade materials. Some key features include:

Our Lifter Bar (Radicial) products are widely used across multiple industrial sectors where

grinding and material processing are key operations.

When it comes to durability, reliability, and performance, Mouldtech Industries stands out as a preferred choice among Lifter Bar (Radical) Products Manufacturers and Suppliers.

Here’s why clients across industries trust us:

Our Lifter Bar (Radicial) products are ideal for:

Grinding and milling operations in ball and SAG mills

Enhancing the lifting and cascading motion of the grinding media

Reducing shell wear and improving liner life

Promoting uniform material distribution and output quality

Supporting energy-efficient and smooth mill operation

If you are looking for a Lifter Bar (Radical) Products Manufacturer in Vadodara or a trusted Manufacturer of Lifter Bar (Radical) Products in Gujarat, Mouldtech Industries is your dependable partner. With our high-quality products, customer-focused service, and technical expertise, we help industries achieve enhanced grinding performance and reduced operational costs. Your trusted Lifter Bar (Radical) Products Manufacturer and Supplier for durable and efficient mill lining solutions. Reach out to us today to discuss your specific requirements for Lifter Bar (Radical) products and experience world-class engineering excellence for your industry needs.

+91-9998003813

info@mouldtechindustries.in

Lifter bars improve the motion of the grinding media, ensuring better impact, reducing wear on the mill shell, and increasing grinding efficiency. Mouldtech Industries’ lifter bars are designed for maximum durability.

Yes. Mouldtech Industries offers fully customized lifter bars to fit any type and size of ball mill, including both wet and dry grinding mills.

A Ball Mill Lifter Bar is a component inside the mill that lifts and cascades the grinding media, enhancing impact and grinding efficiency. Mouldtech Industries manufactures high-quality lifter bars for optimal mill performance.

Lifespan depends on grinding material, mill speed, and maintenance. Mouldtech Industries’ lifter bars are engineered for long-term performance in harsh milling conditions.

Regular inspections, proper installation, and timely replacement of worn bars are essential. Mouldtech Industries provides guidance to maintain lifter bars for optimal operation.

By lifting and cascading the grinding media uniformly, lifter bars increase impact force, reduce slippage, and ensure more efficient grinding.

WhatsApp us