Mouldtech Industries stands as a premier Head End Liner Products Manufacturer, delivering high-quality solutions to diverse industrial sectors. As a trusted Manufacturer of Head End Liner Products in Gujarat and specifically a leading Head End Liner Products Manufacturer in Vadodara, we specialize in crafting products that enhance efficiency, durability, and performance in various applications. Our commitment to precision, reliability, and customer satisfaction has positioned us as a preferred Head End Liner Products Manufacturer and Supplier across India.

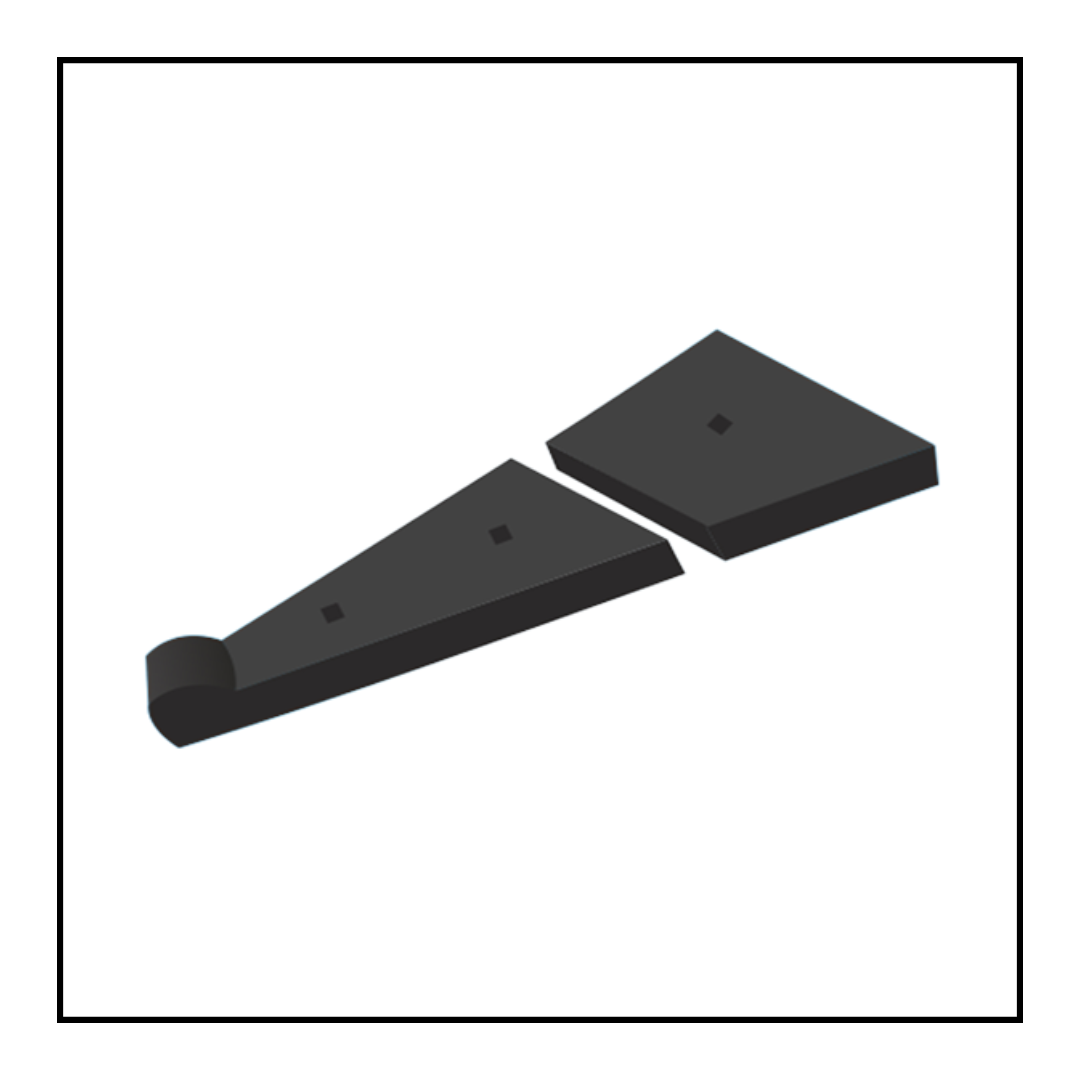

A Head End Liner is a critical component used in industrial machinery and equipment, designed to provide superior protection, wear resistance, and longevity. It is engineered to handle high-stress conditions, reduce operational downtime, and optimize machinery performance. Constructed with premium-grade materials, Head End Liners are essential for industries that demand robust, reliable, and durable machine components.

Our Head End Liner Products are engineered for excellence across multiple industries,

including:

Choosing Mouldtech Industries as your Head End Liner Products Manufacturer comes with

numerous advantages:

The Head End Liner is designed for multiple industrial purposes, including:

Protecting equipment from abrasive materials and reducing wear in high-impact operations. Ensuring seamless operation in crushers, kilns, and grinders. Minimizing maintenance downtime, improving machine efficiency.

Enhancing operational safety and longevity of industrial machinery.

Supporting heavy-duty and high-temperature industrial processes.

Industries such as Cement, Ceramic, Minerals, Mining & Metal, and Energy & Green rely heavily on our Head End Liners for operational efficiency and long-term reliability.

Mouldtech Industries is your one-stop solution for high-quality Head End Liner Products. As a leading Head End Liner Products Manufacturer in Vadodara and a reputed Manufacturer of Head End Liner Products in Gujarat, we are dedicated to providing solutions that maximize efficiency, durability, and performance for your machinery.

Contact us today to explore our wide range of Head End Liners, request a customized solution, or get a quotation. Partner with Mouldtech Industries and experience the difference of working with a trusted Head End Liner Products Manufacturer and Supplier committed to excellence across industries.

As a reputed Wave Liner Products Manufacturer and Supplier, Mouldtech Industries is

committed to offering the highest quality solutions that meet global industry standards.

Here’s why our customers trust us:

As one of the most recognized Manufacturer Of Wave Liner Products in Gujarat, Mouldtech Industries delivers innovative solutions designed to enhance mill performance and extend equipment lifespan. Our liners are trusted by clients in Vadodara and across the country for their precision, durability, and performance reliability. We also cater to export markets, ensuring our global clients receive high-quality, performance-driven products.

At Mouldtech Industries, we are not just manufacturers — we are your trusted partners in industrial performance enhancement. As a leading Wave Liner Products Manufacturer and Supplier, we continue to innovate and evolve, ensuring that every product we deliver meets the dynamic needs of modern industries. Our commitment to quality, innovation, and customer satisfaction makes us a preferred choice for businesses across Mining, Minerals, Ceramic, Cement, Energy, and Manufacturing sectors. If you’re looking for a reliable and efficient Wave Liner Products Manufacturer in Vadodara or anywhere in Gujarat, Mouldtech Industries is your one-stop solution. Our Wave Liners are

crafted with precision, designed for endurance, and proven to deliver superior results in diverse industrial applications. Enhance your mill’s performance, reduce maintenance costs, and ensure long-lasting protection with Mouldtech Industries’ Wave Liner Solutions — where innovation meets

reliability.

Your trusted partner for Wave Liner solutions in India and beyond

+91-9998003813

info@mouldtechindustries.in

A: A ball mill rubber liner is a type of liner made from rubber that is used to protect the ball mill from wear and tear caused by grinding materials.

A ball mill rubber liner can be used to grind a wide range of materials, including minerals, ores, chemicals, and other materials that need to be ground into a fine powder.

The use of a ball mill rubber liner can help to reduce wear and tear on the ball mill, as well as improve the grinding efficiency of the machine. Additionally, the rubber liner can help to reduce noise levels within the ball mill.

The lifespan of a ball mill rubber liner can vary depending on the materials being ground, the size and speed of the ball mill, and other factors. However, in general, a well-designed and well-maintained ball mill rubber liner can last for several years.

WhatsApp us