Rubber Frame Manufacturer, Supplier, And Exporter in India: Mouldtech Industries

Mouldtech Industries is a Manufacturer of Rubber frames in Ahmedabad.

Our Manufacturing Unit is in Vadodara, Gujarat, India.

Mouldtech Industries is a Manufacturer of Ball Mill Solutions, Ball Mill Rubber Lining, Wear Protection Line, Resistant Rubber Liner, Embedded Rubber Liners, Conveyors Solutions, Diamond Pulley Lagging, Belt Cleaners, Pulley Lagging, Ceramic Rubber Lagging Services, and Ceramic Rubber Lagging Sheet.

Rubber Frame: A Critical Wear Protection Component for Modern Industrial Operations

Introduction

In demanding industrial settings, equipment dependability is paramount. Operations such as mining, cement production, metal and steel processing, ceramics manufacturing, and handling of bulk materials subject machinery to constant mechanical strain. Frictional wear, repeated impacts, dampness, and material accumulation progressively damage equipment exteriors, leading to unexpected outages and rising repair costs.

Global industrial needs indicate a consistent drive for longer equipment lifespans, reliable maintenance schedules, and safer plant operations. As facilities expand capacity and automation increases, the margin for unforeseen failures narrows. This has underscored the importance of specialized wear-defense systems capable of withstanding harsh service conditions without compromising fundamental strength.

Against this backdrop, Rubber Frame assemblies have surfaced as a vital industrial remedy. Employed within wear linings, conveying setups, and defensive setups, Rubber Frames function to spread loads, dampen vibrations, and resist wear across numerous sectors.

Challenges Driving Need for Rubber Frame Systems

Seasoned plant supervisors often note that wear-related failures seldom stem from just one cause. Instead, they arise from a confluence of operational stresses:

- Abrasion: In mining and metal refining, continuous contact with minerals, processed materials, or ceramics causes surface erosion. Metal meeting material speeds up degradation if not suitably isolated.

- Impact Forces: Grinding mills, material chutes, and storage bins endure repeated force from descending materials. Without components that soak up energy, structural weakening becomes inevitable.

- Corrosion: Dampness, chemical agents, slurry conditions, and temperature swings promote decay, particularly when protective mechanisms are poorly conceived.

- Outage Pressures: Unscheduled stops impact not only output but also downstream logistics planning, energy use management, and workforce deployment.

- Rising Repair Expenses: Frequent lining replacements and structural repairs significantly increase the total cost of ownership over the equipment’s service life.

Rubber Frame setups address these issues by serving as functional linkages between wear surfaces and primary equipment structures, especially in global industrial settings where operational conditions vary widely.

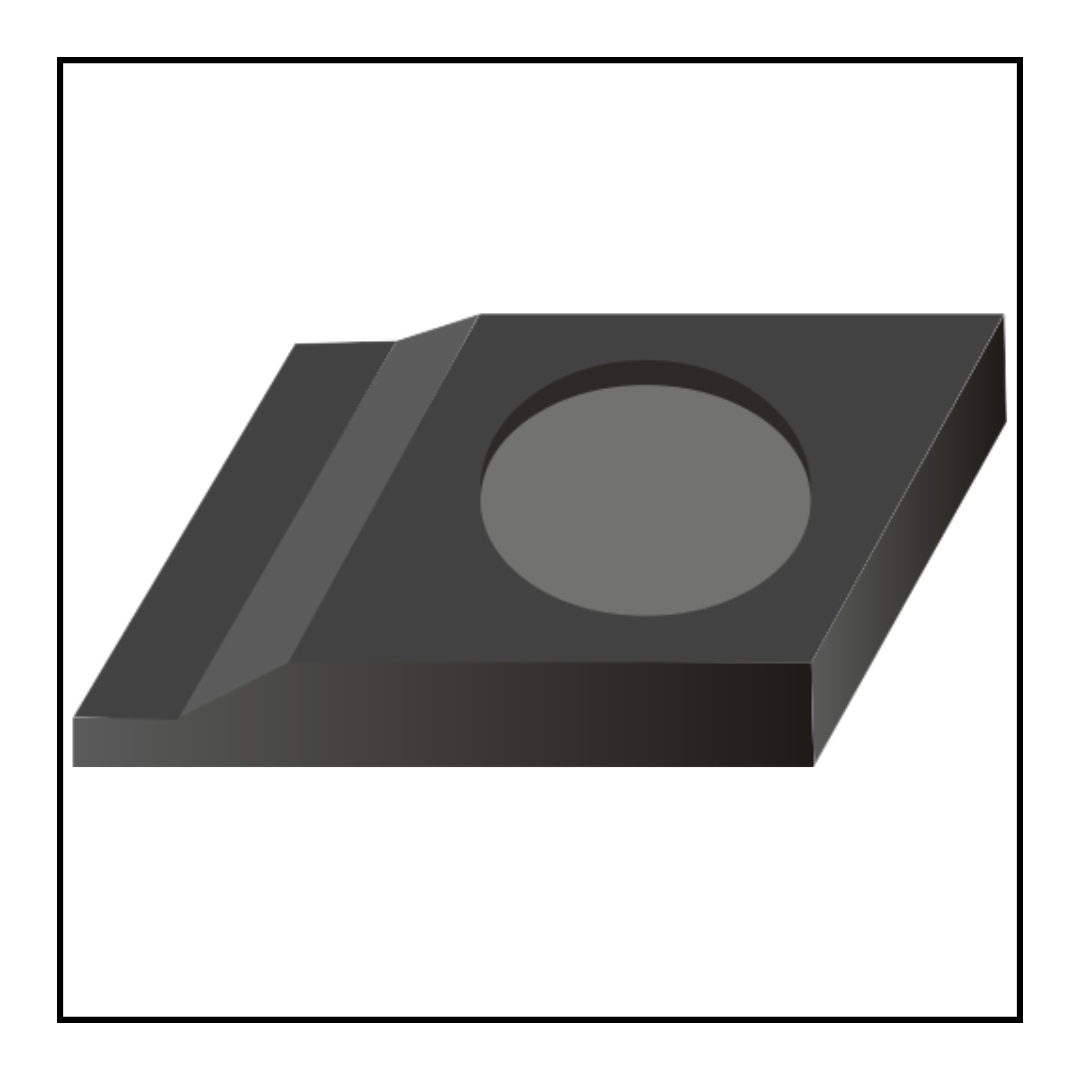

Defining a Rubber Frame

A Rubber Frame is a purpose-built rubber-based structural element intended to support, contain, or join with wear liners, ceramic components, conveyor parts, or protective panels. Unlike simple rubber sheeting, Rubber Frames are components with fixed dimensions and defined capacities for bearing loads and absorbing energy.

From an operational perspective, Rubber Frames fulfill three principal roles:

- Soaking up impact and oscillation

- Shielding wear surfaces from metal frameworks

- Maintaining the proper position and fit of wear defense arrangements

They are routinely incorporated into grinding mill linings, ceramic wear setups, rubber lining systems, and conveyor protection solutions—without needing modification to the base machinery design.

Sector-Specific Uses

- Mining Sector: Rubber Frames are commonly utilized in grinding mills, liquid transport systems, chutes, and material transfer spots. They help reduce the impact load on shell structures while providing support for rubber or ceramic coverings.

- Cement Facilities: In cement grinding and material conveyance, Rubber Frames help manage the movement of abrasive clinker and reduce noise and vibration.

- Metal & Steel Works: Steel handling lines, sintering areas, and material conveyors rely on Rubber Frames to minimize wear at transfer points and safeguard structural elements.

- Ceramic Production: Ceramic clusters in specific Indian regions employ Rubber Frame-backed ceramic wear defense in raw material handling and milling processes.

- Power Generation Stations: Coal handling units incorporate Rubber Frames in chutes, feeders, and conveyor junctions to manage abrasive coal flow and impact forces.

- Bulk Material Handling Systems: Ports, engineering assembly projects, and original-equipment conveyor lines feature Rubber Frames to enhance equipment durability and operational safety.

Material Science & Design Factors

Producers with extensive industry acquaintance know that rubber performance is determined by more than just its firmness.

Rubber Attributes

- Elastic rebound allows for impact cushioning.

- Resistance to tearing preserves structural soundness under repeated force

- Chemical stability supports use in wet or slurry settings

- Ceramic Synergy: When paired with ceramic pieces, Rubber Frames help distribute forces uniformly, cutting the likelihood of ceramic chipping under concentrated loads.

- Wear Resistance Theory: Rubber mitigates wear not through sheer hardness but through energy dissipation and flexing, which explains its effectiveness in high-impact zones.

Tailoring and Customization Needs

No two operational sites share identical conditions. Rubber Frame systems must be engineered accounting for:

- Machine shape and attachment points

- How loads are spread out

- Service temperature and material type

- Compatibility with rubber liners, ceramic tiles, or conveyor parts

Bespoke sizing and application-specific contours ensure Rubber Frames fit in without necessitating alterations to existing machinery.

Manufacturing Excellence & Process Oversight

Precise fabrication is essential for the Rubber Frame’s effectiveness. Dimensional accuracy directly impacts how well liners seat and how stresses are distributed.

Key production controls involve:

- Managed rubber mixture preparation

- Consistency in compression or mold application

- Quality checks for each production lot

- Tracking of raw materials

Uniformity across manufacturing runs ensures reliable field performance—a crucial factor for large enterprises operating across varied sites.

Setup & Servicing Points

From an upkeep viewpoint, Rubber Frames offer tangible benefits:

- Easier fitting using standard implements

- Reduced risk of metal-to-metal interaction

- Predictable wear patterns

Maintenance crews often report shorter downtime and simpler liner swaps when they design and mount rubber frames appropriately.

Safety & Operational Dependability

Worker well-being is closely tied to the state of the equipment. Wear areas with insufficient safeguarding heighten the potential for:

- Abrupt liner breakdowns

- Material escapes

- Structural harm

Rubber Frame setups boost operational reliability by stabilizing wear components and reducing unexpected failures, fostering safer workplaces.

Value for Money Across the Equipment’s Lifespan

While the initial outlay is just one aspect, Rubber Frames provide returns through:

- Increased service duration for liners

- Diminished structural harm

- Streamlined upkeep schedules

Over time, facilities gain from reduced total ownership costs, better on-stream time, and more effective asset utilization—without requiring repeated urgent fixes.

Export Preparedness & Worldwide Recognition

International purchasers anticipate industrial parts to fulfill stringent documentation and performance benchmarks. Rubber Frame systems supplied for overseas markets must conform to:

- Uniformity in size stipulations

- Clarity in material specifications

- Expectations for packing and distribution

Indian fabricators serving the global mining, cement, and metal sectors must showcase methodical procedures and technical awareness.

The Significance of Seasoned Fabricators

The efficacy of a Rubber Frame relies as much on engineering insight as on the raw materials. Producers with genuine plant involvement grasp:

- How issues develop in various sectors

- The installation limitations faced by upkeep crews

- What is expected for long-term performance

This background translates into dependable goods and a steady supply—both vital for industrial functions.

Regarding Mouldtech Industries

Mouldtech Industries is a seasoned manufacturer specializing in rubber wear protection systems, ceramic wear solutions, mill lining rubber products, conveyor parts, and industrial lining systems. Serving industrial areas across India, including Gujarat, Maharashtra, Rajasthan, Odisha, Chhattisgarh, Jharkhand, West Bengal, Tamil Nadu, Andhra Pradesh, Telangana, Karnataka, Madhya Pradesh, Uttar Pradesh, Punjab, Haryana, Himachal Pradesh, Uttarakhand, Bihar, Assam, and other industrial zones, the firm supports mining centers, cement routes, ceramic hubs, and metal processing districts throughout India.

With an awareness of actual plant scenarios and extended operational demands, Mouldtech Industries assists both domestic and export-focused industrial projects.

👉 https://www.mouldtechindustries.in/

Closing Remarks

Rubber Frame systems serve a subtle yet crucial role in contemporary industrial operations. By managing kinetic energy, reducing abrasion, and shielding essential equipment structures, they directly improve plant reliability and maintenance effectiveness.

In sectors where continuous operation dictates competitiveness, well-designed Rubber Frames are not optional additions—they are a component of responsible equipment design and usage.

Main Points to Note

- Rubber Frames absorb impact and lessen abrasive wear

- They improve equipment dependability in harsh settings

- Suitable for mining, cement, metal, ceramic, and bulk handling sectors

- Aid in predictable maintenance scheduling

- Recognized in worldwide industrial arenas

Trending FAQs

Q1. What is the typical service life of a Rubber Frame?

Service life depends on operating conditions, impact load, and material flow, but well-designed systems offer long-term stability.

Q2. Are Rubber Frames suitable for high-impact applications?

Yes, they are specifically engineered to absorb and distribute impact loads.

Q3. How often do Rubber Frames require maintenance?

Teams usually align inspections with liner maintenance cycles rather than requiring separate schedules.

Q4. Rubber vs ceramic wear solutions—which is better?

They serve different functions; rubber absorbs impact, while ceramics resist abrasion. Many systems combine both.

Q5. Are Rubber Frames used globally?

They are widely accepted in the mining, cement, and bulk material-handling industries worldwide.

Contact Mouldtech Industries to discuss Rubber Frame requirements, application challenges, and engineered wear-protection solutions for mining, cement, metal, ceramic, and bulk-material-handling operations.

#RubberFrame #BallMillRubberLiner #CeramicWearProtection #RubberLiningSystems #BallMillRubberProducts #ConveyorSolutions #MiningEquipment #WearProtectionSystems #BulkMaterialHandling #IndustrialRubber #CementPlantEquipment #SteelPlantSolutions #CeramicIndustry #PlantMaintenance #HeavyDutyIndustries