Fitting Accessories Manufacturer, Supplier, And Exporter in India: Mouldtech Industries

Mouldtech Industries is a Manufacturer of Fitting Accessories in Ahmedabad.

Our Manufacturing Unit is in Vadodara, Gujarat, India.

Mouldtech Industries is a Manufacturer of Ball Mill Solutions, Ball Mill Rubber Lining, Wear Protection Line, Resistant Rubber Liner, Embedded Rubber Liners, Conveyors Solutions, Diamond Pulley Lagging, Belt Cleaners, Pulley Lagging, Ceramic Rubber Lagging Services, and Ceramic Rubber Lagging Sheet.

Fitting Accessories in Heavy-Duty Industrial Wear Protection Systems

Introduction

In demanding industrial settings, equipment dependability isn’t just a desirable feature—it’s a core requirement. Sectors such as mining, metal fabrication, cement production, ceramics, and bulk material transport operate under constant mechanical strain, abrasive material movement, and severe environmental conditions. These conditions subject equipment surfaces to intense wear, resulting in frequent servicing needs, unexpected stoppages, and safety hazards.

Across global industrial markets, equipment producers and site operators are increasingly aiming to extend asset life while maintaining consistent operation. Wear mitigation setups are vital in striking this equilibrium. Within these setups, Fitting Accessories serve as crucial components, ensuring proper mounting, load dispersion, and the long-term functionality of wear linings, ceramic defense tiles, rubber lining solutions, and conveyance systems.

When given insufficient attention, even top-tier wear materials can degrade too soon. When meticulously designed, Fitting Accessories directly contribute to operational availability, maintenance effectiveness, and site security.

Industrial Hurdles Driving the Need for Fitting Accessories

In mining and metal processing activities, plant engineers continuously confront a mix of issues that speed up equipment deterioration:

- Intense rubbing from ores, processed rock, coal, dust, and ceramic feedstocks

- High shock forces due to significant material drops and milling media

- Chemical deterioration in slurry transport, wet processing, and areas exposed to chemicals

- Operational halts caused by linings becoming loose, misaligned, or failing prematurely

- Increasing service expenditures stemming from regular component replacement

Global industrial settings—whether iron ore quarries, cement kilns, steel processing facilities, or ceramic slurry setups—require wear solutions that are both robust and properly integrated. Fitting Accessories bridge the gap between wear materials and the equipment structure, ensuring stability under shifting operating conditions.

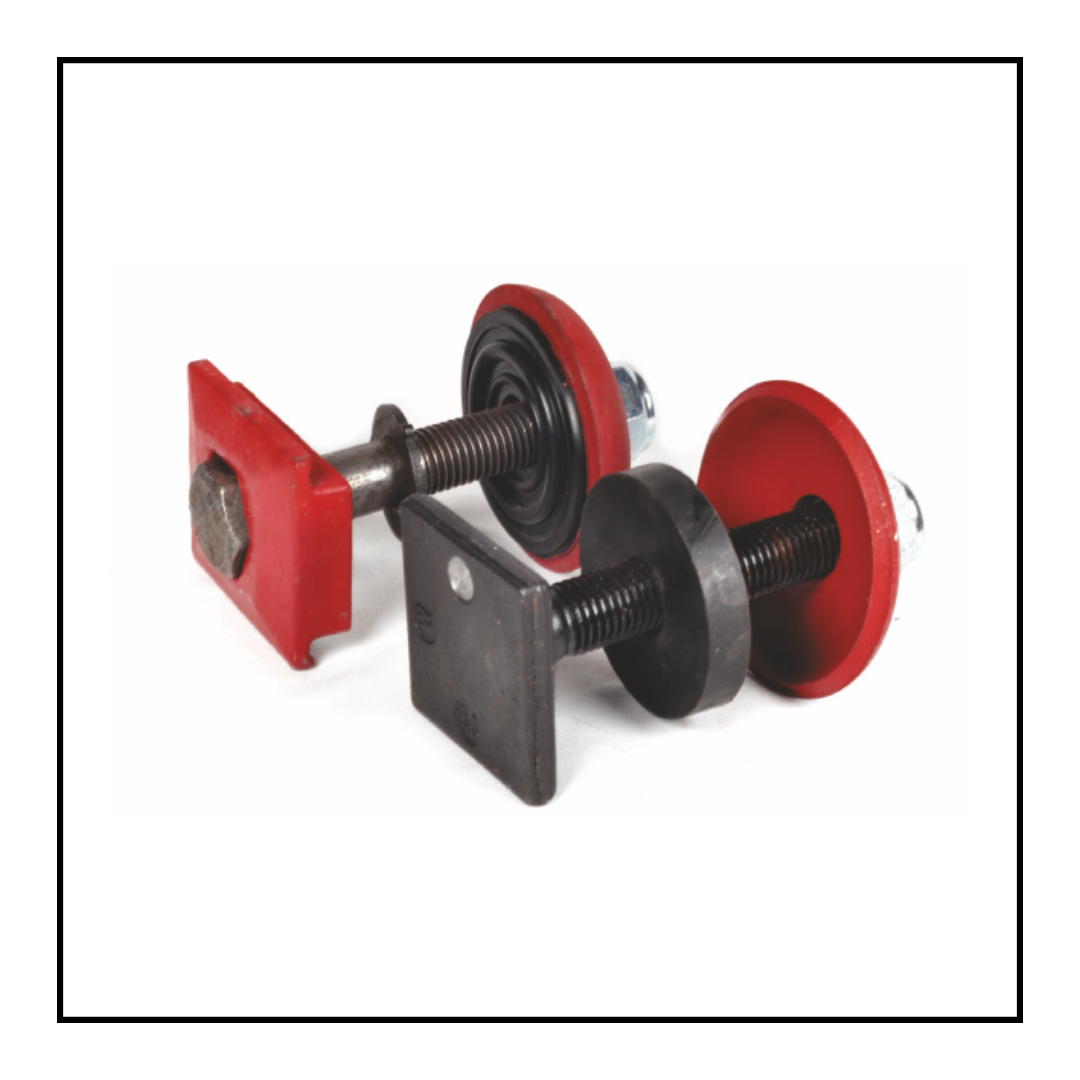

What Are Fitting Accessories?

Fitting Accessories are precision-made parts utilized to mount, secure, adjust, and support wear protection systems and industrial equipment sections. These comprise bolts, support plates, attachment hardware, sealing parts, structural frames, and joining mechanisms engineered to work alongside rubber linings, ceramic wear pieces, conveyor hardware, and lining configurations.

From an industrial viewpoint, Fitting Accessories are not optional additions. They are active components that:

- Hold liners in their correct placement

- Manage secondary strains

- Prevent shifting under vibration and impact

- Aid in secure setup and removal

Their performance directly impacts the service duration and efficacy of the primary wear protection system.

Use Cases Across Industries

Mining Sector

In mining applications, Fitting Accessories are widely used in grinding mills, chutes, storage bins, slurry conduits, and transfer points. Experienced site engineers frequently note that liner failures often commence at inadequately supported attachment points rather than within the lining material itself.

Cement Facilities

Cement creation exposes machinery to abrasive clinker, high temperatures, and constant material throughput. Appropriate Fitting Accessories ensure rubber linings, ceramic defense arrangements, and conveyor parts remain steady during extended service periods.

Metal & Steel Plants

Steel mills involve material handling with significant impact and scale abrasion. Fitting Accessories help maintain liner condition in feed chutes, storage hoppers, and material transfer assemblies.

Ceramic Production

Ceramic plants necessitate accuracy. Fitting Accessories ensure ceramic wear tiles stay aligned, preventing edge damage and uneven wear in slurry-handling and grinding setups.

Power Plants & Bulk Material Transport

Coal handling setups, ash transport lines, and conveyor systems depend on correctly mounted wear components. Inadequately secured systems increase the risk of spills, dust, and service complications.

Material Science & Design Considerations

From an engineering standpoint, Fitting Accessories must complement the material characteristics of wear linings:

- Rubber parts offer flexibility, impact dampening, and vibration control

- Ceramic materials provide exceptional hardness and rub resistance, but need stable support

- Wear reduction principles concentrate on managing friction, spreading load, and lessening pressure points

- Shock absorption is achieved via suitable backing and attachment frameworks

Producers with extensive industry history realize that mismatched materials or flawed fastening design can nullify the advantages of advanced wear materials.

Design & Customization Necessities

Industrial facilities are never truly alike. Equipment shapes, operational settings, and material traits show considerable variation. Therefore, the necessary mounting components must be:

- Conformant with the specific equipment layouts

- Precisely sized for internal coverings, tiles, and conveyance belt setups

- Tailored for the stress profiles particular to the application

Bespoke design guarantees that auxiliary parts do not become weak points during continuous service.

Production Quality & Process Supervision

Exact manufacturing is vital. Industrial-grade mounting hardware demands:

- Precise dimension monitoring

- Uniform material characteristics

- Verification of quality at the batch level

Rigorous adherence to the process ensures consistency and reliability across large-scale deployments, especially in multi-line facilities operating in various locales.

Erection & Servicing Aspects

Simplicity in mounting directly affects periods of inactivity. Thoughtfully designed fitting parts facilitate:

- Quicker replacement of protective layers

- Minimizing the requirement for adjustments on-site

- Predictable upkeep schedules

Service teams gain from standardized fastening arrangements that streamline assessment and renewal procedures.

Safety & Operational Dependability

Workforce protection is closely tied to machinery steadfastness. Unsecured liners, mismatched tiles, or unfastened conveyor elements pose significant risks. Appropriately fitting accessories assist in:

- Averting unintended movement of liners

- Lowering hazards during service operations

- Sustaining uniform machine output

Trustworthy fastening setups contribute to safer facility conditions and regulatory compliance.

Efficiency of Expenditure Across Equipment Lifespan

Although mounting extras constitutes a minor fraction of the entire system, their effect on the total lifecycle expense is considerable. Correctly engineered add-ons result in:

- Prolonged service duration for internal linings

- Fewer unplanned stoppages

- Optimized upkeep scheduling

Value is realized through operational stability, rather than savings achieved only in the short term.

Export Eligibility & Worldwide Acceptance

Global industrial purchasers anticipate wear-mitigation systems that meet universal benchmarks for reporting, material provenance tracing, and consistent performance. Fitting components ready for export demonstrate:

- Understanding of industry benchmarks

- Sound production methods

- Clear technical documentation

Such readiness promotes acceptance across resource-extraction hubs, cement complexes, and metal-processing sectors worldwide.

The Value of Seasoned Producers

In the field of industrial wear mitigation, deep experience leads to fewer failures. Manufacturers possessing extensive sector awareness grasp:

- Actual working environments

- Typical points of breakdown

- Anticipations for long-term operation

Engineering acumen ensures that the mounting components function as intended throughout the equipment’s active service.

Regarding Mouldtech Industries

Mouldtech Industries stands as an experienced industrial producer specializing in linings for grinding mills, solutions for ceramic wear defense, rubber lining systems, grinding mill rubber goods, conveying systems, and related fastening components. Serving industrial markets across India, encompassing numerous states and union territories, the firm supports varied industrial segments throughout India and in international arenas.

Further details are accessible at 👉 https://www.mouldtechindustries.in/

Summary

Mounting Accessories serve a fundamental role in wear-defense setups in industry. Their appropriate engineering, material selection, and setup directly influence machine dependability, protection, and operational effectiveness. In challenging industrial settings, these constituent parts help facilities maintain steady output while addressing long-term maintenance issues.

Principal Takeaways

- Essential backing for wear protection systems

- Enhanced machine steadiness and trustworthiness

- Applicable across mining, cement, metal, ceramic, and bulk material handling sectors

- Sustains enduring operational efficacy

- Acknowledged in global industrial deployments

Trending FAQs

Q1. What is the typical lifespan of fitting accessories?

Lifespan depends on operating conditions, material selection, and maintenance practices.

Q2. Are fitting accessories application-specific?

Yes, they must be designed based on equipment geometry and material flow characteristics.

Q3. How often do fitting accessories require maintenance?

Inspection is usually aligned with liner maintenance cycles.

Q4. How do rubber and ceramic systems affect fitting design?

Rubber requires flexibility, while ceramic systems need rigid, stable support.

Q5. Are these systems used globally?

Yes, fitting accessories are integral to wear systems in industrial plants worldwide.

Contact Mouldtech Industries for Fitting Accessories supporting wear protection, rubber liners, ceramic solutions, and conveyor systems. Our team assists with selection, customization, installation guidance, and supply.

#FittingAccessories #BallMillRubberLiner #CeramicWearProtection #RubberLiningSystems #WearProtectionSolutions #IndustrialRubberProducts #CeramicProtectionSystems #ConveyorSolutions #BulkMaterialHandling #MouldtechIndustries