At Mouldtech Industries, we specialize in designing and manufacturing premium-quality Ball Mill Rubber Lining products that ensure superior performance, long service life, and enhanced grinding efficiency. As a leading Ball Mill Rubber Lining Products Manufacturer in Vadodara, Gujarat, we are committed to delivering innovative and cost-effective solutions for various industries, including Mining & Metal Industries, Minerals Industries, Ceramic

Industries, Cement Industries, Energy & Green Industries, Manufacture & Machine Parts.

Our rubber linings are precisely engineered to provide excellent resistance against wear, impact, and abrasion, making them an ideal choice for ball mills of all sizes and capacities. Mouldtech Industries has earned a strong reputation as a Manufacturer of Ball Mill Rubber Lining Products in Gujarat, known for its consistent quality, precision manufacturing, and customer satisfaction.

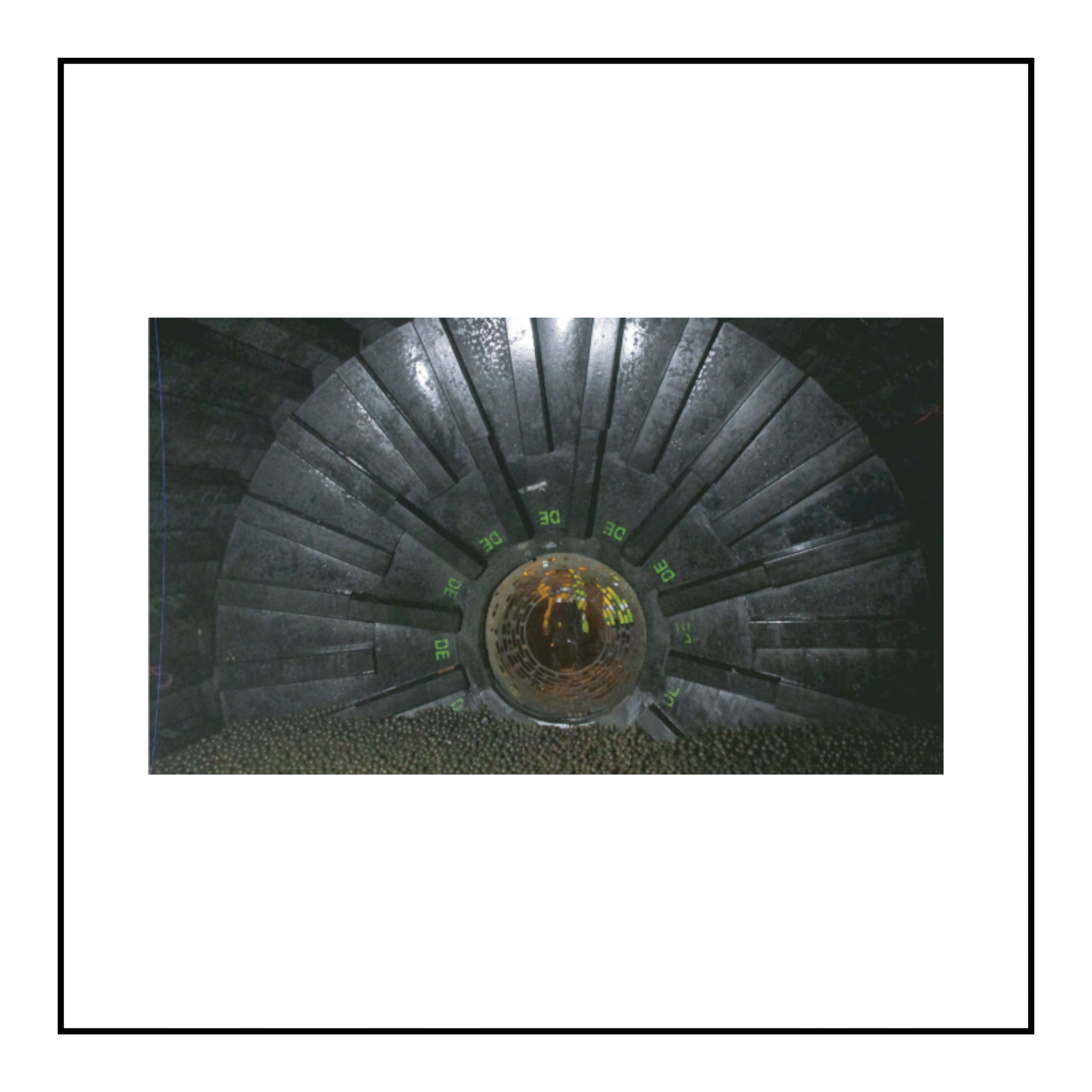

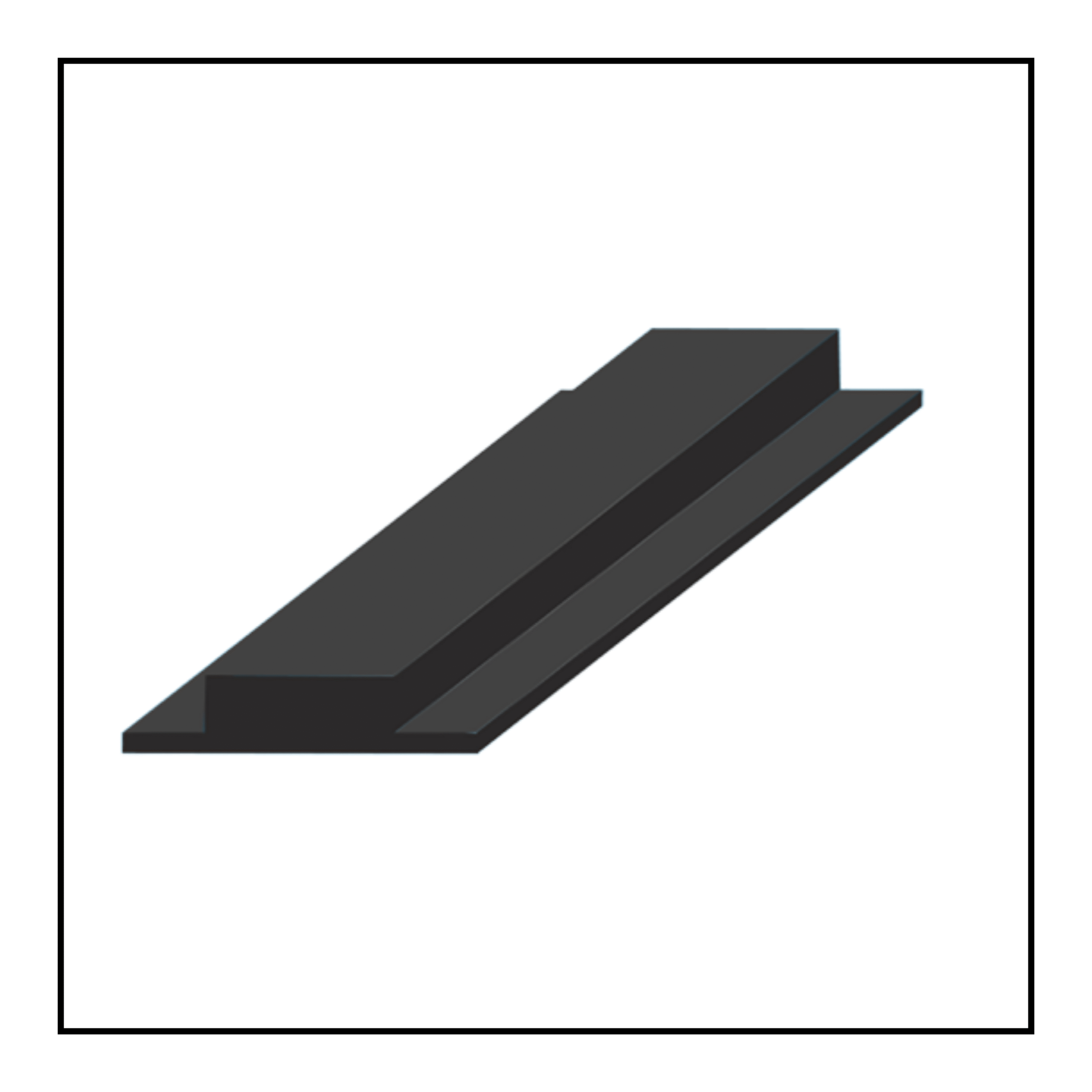

A Ball Mill Rubber Lining is a protective layer made from premium rubber compounds that lines the inside surface of ball mills. It serves as a barrier between the mill shell and the grinding material, reducing wear and tear, minimizing noise, and improving mill efficiency. At Mouldtech Industries, we use high-grade natural and synthetic rubber materials combined with advanced compounding techniques to create durable linings that perform

reliably under extreme operating conditions.

Key Features of Our Ball Mill Rubber Linings:

As a reputed Ball Mill Rubber Lining Products Manufacturer and Supplier, Mouldtech Industries focuses on quality, innovation, and customer satisfaction. Our products are designed to deliver superior performance while extending the service life of your mill equipment. We offer a comprehensive range of rubber lining products suitable for various industrial applications. Our linings are custom-manufactured to meet specific mill dimensions and

operational requirements.

Product Range Includes:

Each product undergoes strict quality inspection to ensure it meets international standards of durability and efficiency.

Located in the industrial hub of Vadodara, Gujarat, Mouldtech Industries operates a state of-the-art manufacturing facility equipped with modern machinery, precision tools, and skilled engineers. Being a prominent Manufacturer of Ball Mill Rubber Lining Products in Gujarat, we serve clients not only across India but also in global markets. Our expertise lies in creating rubber linings that enhance mill productivity and reduce downtime, making operations smoother

and more profitable.

We prioritize:

Ball Mill Rubber Lining is widely used across industries that involve grinding or milling processes. Its ability to protect the mill shell and optimize grinding operations makes it indispensable in heavy-duty industries.

Common Applications Include:

By using Ball Mill Rubber Lining, industries can reduce maintenance costs, improve operational efficiency, and ensure longer mill life.

When it comes to Ball Mill Rubber Lining Products, Mouldtech Industries stands as a symbol of trust, technology, and top-quality craftsmanship. Here’s why we are the preferred Ball Mill Rubber Lining Products Manufacturer in Vadodara:

Mouldtech Industries has emerged as a leading Ball Mill Rubber Lining Products Manufacturer and Supplier known for reliability and innovation. Our products are used in domestic as well as international markets, trusted by industries that demand consistent performance under rigorous conditions.

We continuously invest in R&D to improve product quality, enhance wear resistance, and develop new rubber formulations that meet evolving industrial requirements. Our mission is to deliver long-lasting, cost-effective, and high-performance solutions that help our customers achieve optimal productivity and profitability.

Looking for durable and high-quality Ball Mill Rubber Lining solutions? Partner with Mouldtech Industries, the most trusted Ball Mill Rubber Lining Products Manufacturer in Vadodara and across Gujarat.

+91-9998003813

info@mouldtechindustries.in

A: A ball mill rubber liner is a type of liner made from rubber that is used to protect the ball mill from wear and tear caused by grinding materials.

A ball mill rubber liner can be used to grind a wide range of materials, including minerals, ores, chemicals, and other materials that need to be ground into a fine powder.

The use of a ball mill rubber liner can help to reduce wear and tear on the ball mill, as well as improve the grinding efficiency of the machine. Additionally, the rubber liner can help to reduce noise levels within the ball mill.

The lifespan of a ball mill rubber liner can vary depending on the materials being ground, the size and speed of the ball mill, and other factors. However, in general, a well-designed and well-maintained ball mill rubber liner can last for several years.

WhatsApp us