When it comes to efficient conveyor belt cleaning systems, Mouldtech Industries stands as a trusted name in the industry. As a prominent Manufacturer Of Primary Belt Cleaner, we specialize in delivering innovative, durable, and high-performance solutions designed to enhance productivity and reduce maintenance downtime across a range of industries. Our Primary Belt Cleaner Products are engineered with precision to remove carryback material from conveyor belts effectively, ensuring optimal performance and a longer lifespan of the conveyor system.

Mouldtech Industries is a renowned Primary Belt Cleaner Manufacturer in Vadodara with a strong focus on quality, innovation, and customer satisfaction. We are committed to producing superior belt cleaning systems that meet the global standards of safety and efficiency. With advanced technology, expert craftsmanship, and years of industrial experience, we have become a leading Manufacturer Of Primary Belt Cleaner in Gujarat, serving both domestic and international markets. Our products are widely utilized in Mining & Metal Industries, Minerals Industries, Ceramic Industries, Cement Industries, Energy & Green Industries, and Manufacturer & Machine Parts sectors, where maintaining clean conveyor belts is crucial for consistent material flow and process reliability.

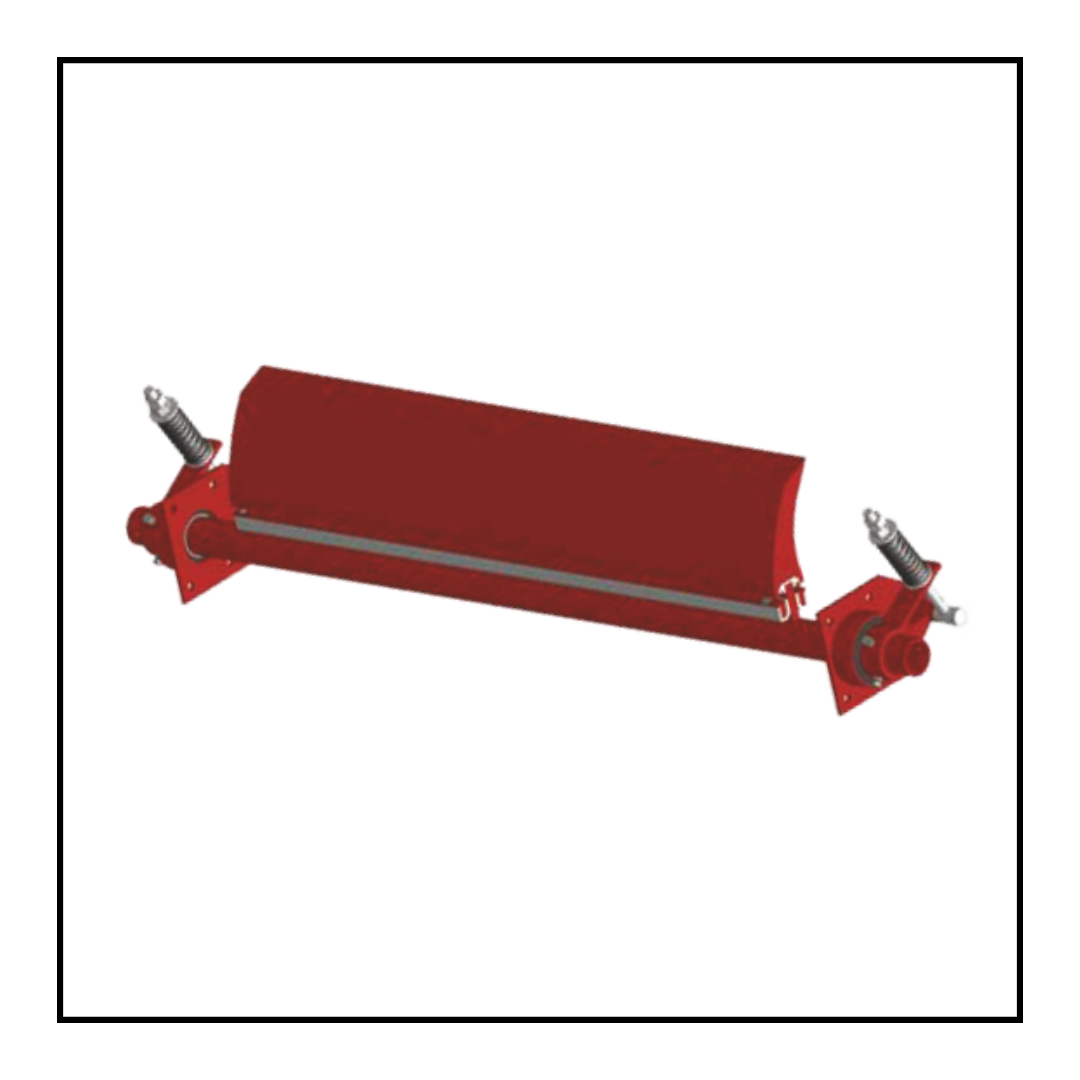

A Primary Belt Cleaner is a vital component installed at the head pulley of a conveyor belt to scrape off the bulk material that adheres to the belt surface. It is the first line of defense against carryback material, ensuring that the conveyor operates cleanly and efficiently. Designed for high-performance and long-lasting durability, our Primary Belt Cleaner Products effectively minimize belt wear, reduce cleanup costs, and prevent material loss, thereby optimizing your operational efficiency.

As a reputed Primary Belt Cleaner Manufacturer and Supplier, we ensure every product undergoes strict quality checks to deliver reliable and efficient performance across all industrial applications.

Our Primary Belt Cleaner Products are used in a wide variety of sectors where conveyor systems play a crucial role in transporting materials. These include:

At Mouldtech Industries, we take pride in being a top-tier Manufacturer Of Primary Belt Cleaner in Gujarat. Our commitment to excellence and customer satisfaction sets us apart in the market. Here’s why you should choose us:

As a reliable Primary Belt Cleaner Manufacturer and Supplier, Mouldtech Industries delivers value through superior engineering, robust design, and exceptional service. If you are looking for a trusted and professional Primary Belt Cleaner Manufacturer in Vadodara or a dependable Manufacturer Of Primary Belt Cleaner in Gujarat, look no further than Mouldtech Industries. Our products are designed to enhance the performance, safety, and efficiency of your conveyor systems across diverse industrial applications. Choose Mouldtech Industries — your reliable Primary Belt Cleaner Manufacturer and Supplier — for world-class solutions that ensure clean conveyors, smooth operations, and long-term reliability.

+91-9998003813

info@mouldtechindustries.in

A: A ball mill rubber liner is a type of liner made from rubber that is used to protect the ball mill from wear and tear caused by grinding materials.

A ball mill rubber liner can be used to grind a wide range of materials, including minerals, ores, chemicals, and other materials that need to be ground into a fine powder.

The use of a ball mill rubber liner can help to reduce wear and tear on the ball mill, as well as improve the grinding efficiency of the machine. Additionally, the rubber liner can help to reduce noise levels within the ball mill.

The lifespan of a ball mill rubber liner can vary depending on the materials being ground, the size and speed of the ball mill, and other factors. However, in general, a well-designed and well-maintained ball mill rubber liner can last for several years.

WhatsApp us