Mouldtech Industries, a trusted name in industrial wear solutions, proudly presents its premium range of Impact Bars – designed to provide unmatched protection, efficiency, and reliability across various industries. As a leading Impact Bar Products Manufacturer, Mouldtech Industries offers world-class solutions that enhance conveyor performance and extend equipment life.

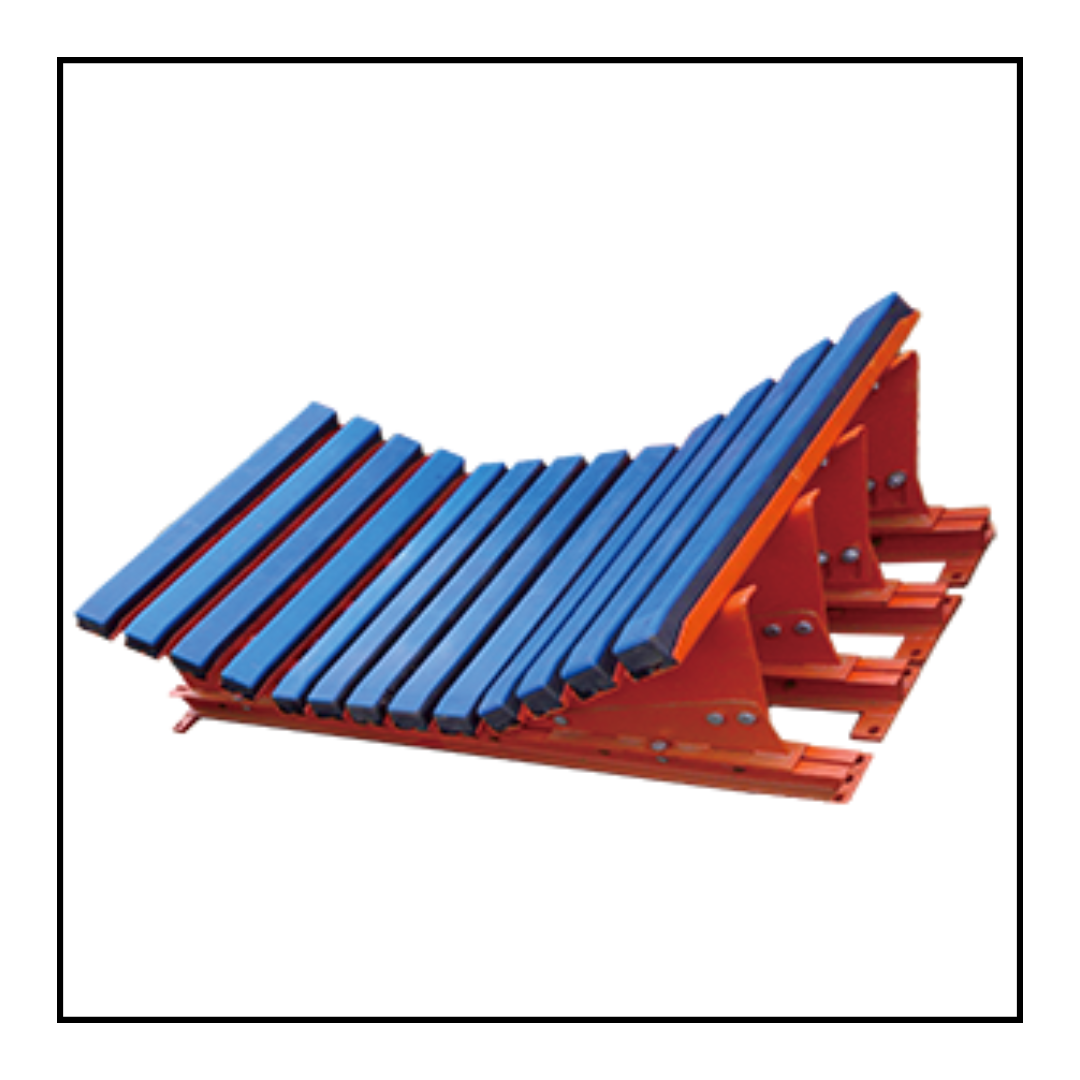

An Impact Bar is an essential component used in conveyor systems to absorb impact forces at loading points, preventing belt damage and reducing maintenance costs. Unlike conventional rollers, Impact Bars are made from a combination of high-quality rubber and ultra-high molecular weight polyethylene (UHMWPE) top surfaces, providing superior wear resistance and smooth belt movement. These bars act as a cushion between the conveyor belt and the materials being loaded, ensuring consistent operation even in the harshest working environments. With their high strength, low friction, and long-lasting performance, Mouldtech Industries’ Impact Bars are the ideal choice for modern material handling systems.

As a reputed Manufacturer of Impact Bar, Mouldtech Industries specializes in delivering durable, efficient, and cost-effective wear protection solutions. With advanced manufacturing technology, stringent quality control, and expert engineering, the company ensures every Impact Bar meets global performance standards. Headquartered in Vadodara, Gujarat, Mouldtech Industries is widely recognized as a leading Impact Bar Manufacturer in Vadodara and a prominent Manufacturer of Impact Bar in Gujarat. With a commitment to innovation and quality, Mouldtech serves clients across

Mining & Metal Industries, Minerals Industries, Ceramic Industries, Cement Industries, Energy & Green Industries, and Manufacture & Machine Parts sectors.

Mouldtech’s Impact Bars are engineered for versatility and are widely used in several industrial sectors:

Installed at conveyor loading points to prevent belt damage.

Provides support and shock absorption for conveyor belts.

Replaces conventional rollers to minimize friction and vibration.

Ensures belt alignment and prevents spillage.

Reduces maintenance costs and improves operational efficiency.

Suitable for both dry and wet material handling applications.

When it comes to Impact Bar Manufacturer and Supplier, Mouldtech Industries stands out due to its unwavering dedication to quality, innovation, and customer satisfaction.

As a trusted Impact Bar Manufacturer in Vadodara and a leading Manufacturer of Impact Bar in Gujarat, Mouldtech Industries continues to set benchmarks for quality and reliability. Whether you operate in Mining, Minerals, Ceramics, Cement, Energy, or Manufacturing, Mouldtech’s Impact Bars are engineered to deliver unmatched protection, performance, and efficiency.

If you’re looking for durable, cost-effective, and high-performance impact protection solutions, Mouldtech Industries is your go-to partner. As a trusted Impact Bar Manufacturer and Supplier, Mouldtech ensures every product meets the highest industry standards and supports your operation’s success.

Experience superior quality, exceptional service, and long-lasting reliability with Mouldtech Industries – India’s trusted name in Impact Bar manufacturing.

+91-9998003813

info@mouldtechindustries.in

A Ball Mill Impact Bar is a protective component installed inside the mill to absorb the shock of falling grinding media, protecting the mill shell and liners. Mouldtech Industries manufactures high-quality Impact Bars designed for durability and optimal performance.

Impact Bars reduce wear and damage to the mill shell and liners caused by high-velocity grinding media, increasing the life of the mill components and improving overall grinding efficiency.

Mouldtech Industries uses premium-grade steel and rubber composites to produce Impact Bars that offer superior impact absorption, wear resistance, and long service life.

They protect liners from premature wear, minimize vibration, and ensure smoother motion of grinding media, leading to more efficient grinding and reduced maintenance costs.

Yes. Mouldtech Industries designs custom Impact Bars tailored to mill size, media type, and operating conditions for optimal performance and protection.

Yes. Mouldtech Industries Impact Bars are effective in both wet and dry grinding environments, providing consistent protection under all conditions.

WhatsApp us