Rubber Plug Manufacturer, Supplier, And Exporter in India: Mouldtech Industries

Mouldtech Industries is a Manufacturer of Rubber Plug in Ahmedabad.

Our Manufacturing Unit is in Vadodara, Gujarat, India.

Mouldtech Industries is a Manufacturer of Ball Mill Solutions, Ball Mill Rubber Lining, Wear Protection Line, Resistant Rubber Liner, Embedded Rubber Liners, Conveyors Solutions, Diamond Pulley Lagging, Belt Cleaners, Pulley Lagging, Ceramic Rubber Lagging Services, and Ceramic Rubber Lagging Sheet.

Rubber Plug: A Critical Wear-Protection Component in Heavy-Duty Industrial Operations

Introduction

In strict industrial settings like mining, cement production, metalwork, ceramics, and the handling of large volumes of material, how well equipment functions directly impacts how much is produced. Hard particles, constant heavy forces, corrosive substances, and extended operating periods create ongoing deterioration challenges for equipment such as grinders, conveyors, delivery chutes, holding tanks, and other processing machinery.

Plant supervisors and maintenance staff continually face similar operational challenges: premature component failures, unexpected stoppages, rising maintenance costs, and safety hazards associated with frequent repairs. As industry expands across India and major global manufacturing centers, the need for reliable means to guard against wear continues to increase.

Against this backdrop, the Rubber Plug holds a small yet vital position. Despite often being overlooked, these rubber parts are necessary for sealing, shielding, and isolating openings in industrial gear prone to wear. When properly designed, they directly improve how long machinery lasts, how safe operations are, and how efficiently maintenance can be performed.

Operational Hurdles Raising the Need for Rubber Plug Options

Seasoned plant engineers frequently note that wear damage seldom happens on its own. It usually stems from several stressors acting together.

Main industrial issues include:

- Wear from Rubbing: Constant contact with rock, ground cement, fuel, minerals, and ceramic material causes surface erosion.

- Forceful Impacts: Ball mills, chutes, and transfer points generate repeated impact energy.

- Rust and Decay: Moisture, chemical agents, slurry conditions, and temperature swings speed up material breakdown.

- Rush to Avoid Delays: Any unscheduled halt immediately impacts production targets.

- Upkeep Expenses: Frequent replacement of minor parts increases overall ownership costs.

In mining and metal-refining operations throughout India—spanning key industrial regions like Odisha, Jharkhand, Chhattisgarh, Rajasthan, Gujarat, Maharashtra, Tamil Nadu, Karnataka, Andhra Pradesh, Telangana, West Bengal, and Madhya Pradesh—facilities operate in harsh, abrasive environments. Similar problems exist in cement production centers, ceramic hubs, and bulk material movement sites in all major Indian industrial areas.

Rubber plugs are specifically designed to address localized stress points where metal breakdown, leaks, or exposure of the inner lining would otherwise cause a fault.

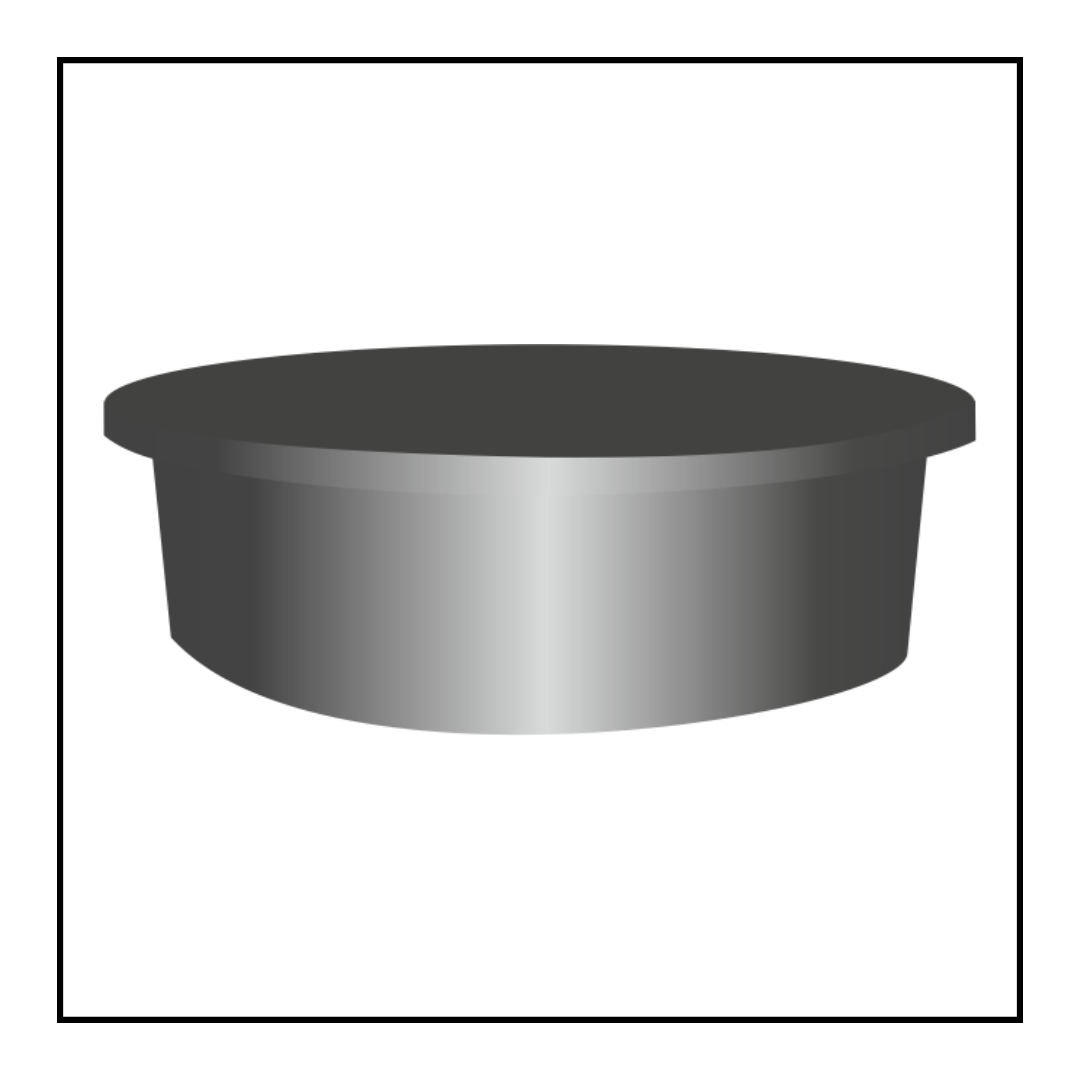

What Exactly Is a Rubber Plug?

A Rubber Plug is a specially made elastic component utilized to block, seal, or safeguard apertures in industrial machinery. In systems designed to resist wear, rubber plugs are commonly employed in:

- Liners for ball mills

- Rubber lining setups

- Tanks and chutes are protected against wear

- Conveyor and material transfer assemblies

Unlike solid metal plugs, rubber plugs offer adaptability, absorb shocks, and maintain a tight seal. Their primary purpose isn’t to bear heavy structural loads but to offer defense—preventing unwanted material entry, lessening concentrated wear, and permitting controlled access for servicing.

From a technical standpoint, a rubber plug needs to balance flexibility, resistance to wear, and retention of shape under continuous operating stress.

Uses Across Different Sectors

- Mining Sector: In mining activities, rubber plugs are used in ball mills, slurry transfer systems, and lined containers. They safeguard bolt holes for liners and inspection openings from erosion and exposure to ore and slurry.

- Cement Facilities: Cement grinding mills and material movement systems use rubber plugs to separate areas subject to wear and keep the liner system intact under ongoing impact and shaking.

- Metal & Steel Plants: Steel plants use rubber-lined gear for processing raw materials, making pellets, and moving materials. Rubber plugs prevent corrosive materials from entering and reduce localized metal deterioration.

- Ceramic Production: Tanks, mills, and processing units handling ceramic slurry benefit from rubber plugs that resist abrasion from tiny ceramic particles and chemical exposure.

- Power Plants: Coal-handling and ash-slurry systems incorporate rubber plugs in lined piping and transfer equipment to enhance protection against wear.

- Bulk Material Handling: Conveyors, chutes, and storage bins at ports, logistics centers, and industrial terminals rely on rubber plugs to maintain sealing effectiveness in high-wear areas.

Material Science & Engineering Aspects to Consider

Producers with extensive field experience know that how Rubber performs depends on its makeup, not just how it looks.

Important material aspects include:

- Elasticity Measure: Governs how well it soaks up impact without deforming too much.

- Resistance to Wear: Vital for environments with constant material flow.

- Resistance to Tearing: Prevents the plug from failing during fitting or while in use.

- Chemical Suitability: Important when dealing with slurry, acidic, or alkaline conditions.

- Heat Stability: Maintains performance across the operating temperature range.

In specific applications, rubber plugs work alongside ceramic wear-resistant pieces, where ceramics provide hardness and rubber delivers energy dampening. This combined approach to wear defense improves the system’s overall reliability.

Design & Customization Needs

Industrial rubber plugs seldom fit every situation perfectly. Design must take into account:

- The shape of the equipment

- The depth of the liner

- The pressure under which it operates

- The way it is installed

- How easy is it to access the service

Tailored sizing guarantees a correct, tight fit and long-lasting sealing. Designs tailored to the job reduce stress points and prevent the plug from loosening while the machine is running.

Manufacturing Quality & Process Checks

Precise manufacturing is crucial for rubber plugs used in industrial settings.

Key steps in quality control include:

- Controlled mixing of rubber compounds

- Accurate construction of the mold

- Checking the final dimensions

- Testing for consistency between production batches

- Visual and physical evaluation of quality

Consistency across production runs leads to predictable results and less variation in maintenance needs for plant operators.

Fitting and Servicing Notes

From a maintenance viewpoint, rubber plugs should allow for:

- Simple placement without needing special tools

- Firm holding in place during operation

- Easy removal when liners need changing

- Minimal impact on operational uptime

Correctly designed rubber plugs help shorten service intervals and boost equipment availability.

Safety & Dependability in Operation

Safeguarding personnel remains paramount within industrial facilities.

Rubber plugs enhance safety through:

- Stopping material escape

- Limiting contact with sharp metal

- Cutting down on unforeseen adjustments

- Aiding in steady lining setups

Small components enhance operational dependability by maintaining steady performance over long periods.

Value Across the Equipment Lifespan

Though rubber plugs are minor parts, their effect on efficiency throughout the equipment’s life is substantial.

Advantages encompass:

- Less damage to linings

- Reduced need for upkeep

- Fewer sudden halts of operations

- Better scheduling of service tasks

Savings over time come from proactive wear defense instead of fixing problems as they arise.

Preparing for International Trade & Worldwide Approval

Worldwide industrial purchasers anticipate wear-defense parts to meet uniform quality standards.

Readiness for export entails:

- Tracking material origins

- Precise sizing and shape

- Adherence to paperwork rules

- Knowledge of global operating settings

Rubber plug designs tailored for the Indian industry are often effective in mining and processing activities worldwide.

The Importance of Seasoned Producers

Manufacturers with extensive sector expertise offer value beyond mere goods supply. They comprehend:

- Actual facility settings

- Ways things can fail

- Limits during fitting

- Practical aspects of upkeep

This hands-on familiarity ensures components function dependably, not just in concept.

Regarding Mouldtech Industries

Mouldtech Industries is a seasoned producer specializing in rubber linings for ball mills, ceramic lining systems, rubber items for ball mills, conveyor systems, and related wear-defense parts such as rubber plugs.

Serving all major industrial regions and population centers across India—and supporting worldwide industrial sectors—the firm emphasizes tailored solutions grounded in practical industrial experience.

Further details can be found at 👉 https://www.mouldtechindustries.in/

Summary

Rubber plugs might seem like small elements, yet their function in industrial wear protection is noteworthy. When designed and utilized appropriately, they directly contribute to equipment trustworthiness, personnel well-being, and sustained operational effectiveness.

In challenging industrial settings, focusing on these vital specifics frequently dictates overall facility performance.

Main Points to Remember

- Rubber plugs safeguard vital parts susceptible to wear at openings

- They improve containment, shock absorption, and the wholeness of liners

- Applicable across mining, cement, metal, ceramic, and bulk handling sectors

- Promote safer work and fewer interruptions from maintenance

- Demonstrated usefulness in both Indian and worldwide industrial settings

Trending FAQs

Q1. What is the typical lifespan of an industrial rubber plug?

Lifespan depends on abrasion level, impact exposure, and operating conditions. Proper material selection significantly extends service life.

Q2. Are rubber plugs suitable for high-impact applications?

Yes, when designed with appropriate rubber hardness and elasticity.

Q3. How often do rubber plugs require maintenance?

They are typically inspected during scheduled liner or equipment maintenance cycles.

Q4. Rubber vs ceramic wear solutions—how do they differ?

Rubber absorbs impact and vibration, while ceramics offer extreme abrasion resistance. They are often used together.

Q5. Are rubber plugs used globally in heavy industries?

Yes, they are standard components in mining, cement, and material handling operations worldwide.

Contact Mouldtech Industries for reliable Rubber Plug solutions engineered for demanding industrial environments. Connect with our team for technical guidance and project support.

#RubberPlug #IndustrialRubber #WearProtection #RubberLining #MiningSolutions #CementIndustry #MetalProcessing #BulkMaterialHandling #BallMillComponents #ConveyorSolutions #MouldtechIndustries