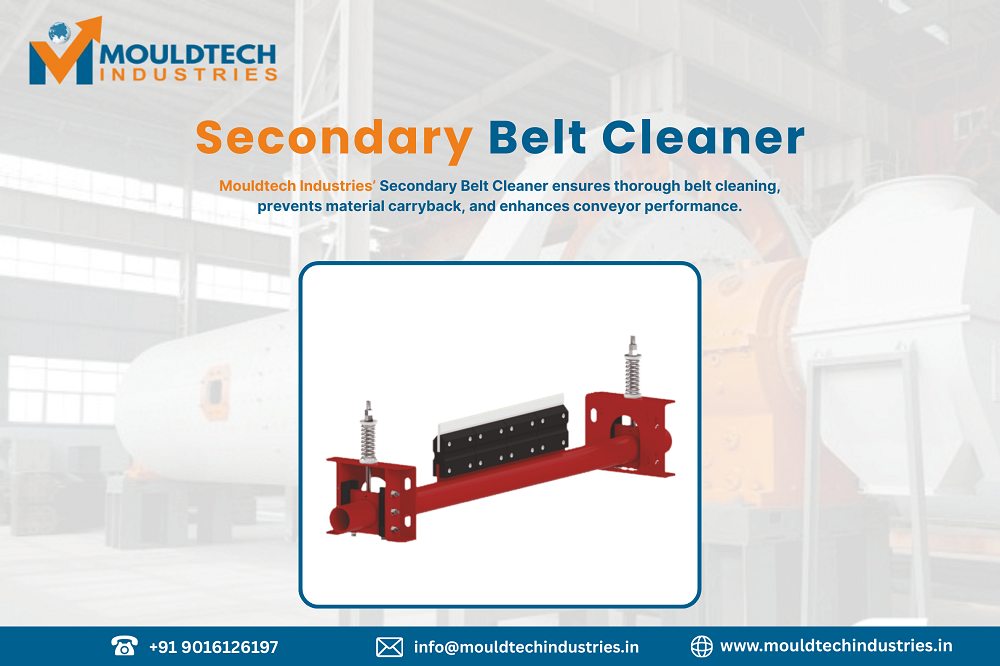

Secondary Belt Cleaner Manufacturer in India: Mouldtech Industries

Mouldtech Industries is a Manufacturer, Supplier, and Exporter of Secondary Belt cleaners.

Our Manufacturing Unit is in Vadodara, Gujarat, India.

Mouldtech Industries is a Manufacturer of Ball Mill Solutions, Ball Mill Rubber Lining, Wear Protection Line, Resistant Rubber Liner, Embedded Rubber Liners, Conveyors Solutions, Impact Bed Assembly and Impact Pads, Belt Cleaners, Pulley Lagging, Ceramic Rubber Lagging Services, and Ceramic Rubber Lagging Sheet.

Secondary Belt Cleaner: Enhancing Plant Efficiency and Wear Protection in Heavy-Duty Industrial Environments

Introduction

In heavy-duty industrial environments such as mining, metal processing, cement manufacturing, ceramics production, and bulk material handling, equipment reliability and operational efficiency are paramount. Plants across Pan India—including Maharashtra, Gujarat, Rajasthan, Tamil Nadu, Karnataka, Odisha, Chhattisgarh, and Madhya Pradesh—routinely face challenges posed by abrasive materials, high-impact loads, and continuous operation. Globally, industrial hubs from Australia’s mining regions to China’s steel and ceramic centers face similar pressures, demanding robust solutions that minimize downtime and maximize productivity.

One critical component in achieving operational reliability is the Secondary Belt Cleaner. While seemingly simple, it addresses one of the most persistent industrial problems: the buildup of material on conveyor belts. Left unmanaged, residual materials can accelerate belt wear, increase maintenance frequency, and even create safety hazards. By implementing engineered secondary belt cleaning systems, plant engineers can mitigate these risks while improving material flow and extending the lifespan of their conveyor infrastructure.

Industrial Challenges That Drive Demand for Secondary Belt Cleaners

In mining and metal processing operations, experienced plant engineers often observe that conveyors are subjected to a combination of extreme stresses:

- Abrasion: Minerals, ores, and clinker often have sharp, jagged edges. As they move along conveyor belts, they create frictional wear that can degrade both the belt surface and pulley components. Secondary belt cleaners help remove residual particles before they accumulate, reducing abrasion-related damage.

- Impact Loads: Heavy bulk materials drop from chutes or hoppers onto belts, creating localized impact stresses. These impacts, repeated over time, contribute to premature belt damage, misalignment, and pulley wear.

- Corrosion: In cement plants and metal industries, high humidity and exposure to chemical dust can cause corrosion of metallic components in conveyor systems. Secondary belt cleaners with corrosion-resistant materials minimize this exposure.

- Downtime: Residual material on belts can cause unscheduled maintenance shutdowns. Removing these deposits efficiently prevents cascading downtime that affects the entire plant process.

- Maintenance Costs: Frequent belt cleaning without engineered solutions often requires manual labor, increasing operational costs and raising safety concerns for plant personnel.

Globally, industrial environments in countries such as India, South Africa, Brazil, and Australia share similar operational demands, making secondary belt cleaners an indispensable component of modern material handling systems.

What Is a Secondary Belt Cleaner?

A Secondary Belt Cleaner removes material from conveyor belts after primary cleaning, ensuring cleaner operation and improved conveyor efficiency. Unlike primary cleaners, which scrape off the majority of material, secondary cleaners target residual fines and sticky substances that escape initial cleaning.

Key engineering aspects include:

- High-tensile rubber or polyurethane blades are designed to flex under load while maintaining contact with the belt.

- Adjustable tensioning systems to accommodate belt speed, material type, and load.

- Resistance to wear, impact, and chemical exposure depends on operational conditions.

By focusing on residual material, secondary cleaners protect downstream equipment, reduce maintenance interventions, and enhance plant safety and reliability.

Applications Across Industries

- Mining: Mining operations involve the transport of ores, coal, and aggregates with high abrasive content. In these environments, secondary belt cleaners reduce carry-back, protect tail pulleys, and prevent material buildup that can jam idlers and pulleys.

- Cement: Cement plants handle clinker, limestone, and gypsum, all of which are fine, abrasive, and sometimes chemically reactive. Secondary cleaners help reduce belt wear and dust emissions, improving overall material handling efficiency.

- Metal & Steel: Conveyor systems in steel mills and metal processing plants often handle hot, heavy, and sharp metal scraps or slag. Secondary belt cleaners prevent residual metal particles from damaging rollers or causing misalignment, thereby reducing maintenance cycles.

- Ceramic: Ceramic manufacturers of tiles, sanitaryware, and other products rely on secondary cleaners to remove fine clay, glaze residues, and crushed ceramic material from belts, ensuring smooth downstream operations.

- Power Plants & Bulk Material Handling: Coal and ash handling in thermal power plants, along with other bulk handling facilities, benefit from secondary cleaners to minimize spillage, reduce environmental contamination, and maintain plant reliability.

Material Science & Engineering Considerations

The performance of a secondary belt cleaner is heavily influenced by the materials used:

- Rubber Properties: High-quality rubber must exhibit flexibility, tensile strength, and abrasion resistance. Blends are often engineered to withstand heavy impact while maintaining consistent cleaning efficiency.

- Ceramic Hardness: In specific cases, ceramic inserts or hybrid designs are used to enhance abrasion resistance in highly abrasive environments, combining hardness with impact tolerance.

- Wear Resistance Principles: Material selection considers Mohs hardness, elasticity, and fatigue resistance. The goal is to balance blade stiffness with the ability to flex over pulleys without chipping or excessive wear.

- Impact Absorption: Rubber and polyurethane materials absorb impact energy from falling bulk materials, protecting the belt surface and extending component life.

In heavy-duty industrial environments, these engineering considerations are essential to optimize the performance and longevity of secondary belt cleaners.

Design & Customization Requirements

Experienced manufacturers understand that no two conveyor applications are identical. Custom design parameters include:

- Equipment Compatibility: Secondary cleaners must fit the existing conveyor profile, pulley diameter, and belt width without causing interference or misalignment.

- Custom Sizing: Blade length, thickness, and angle are adjusted according to belt speed, material type, and operational environment.

- Application-Specific Design: For corrosive, high-temperature, or ultra-abrasive materials, specialized blade compounds and mounting hardware are selected.

Plant engineers often collaborate with manufacturers to ensure the cleaner design aligns with operational goals and reduces long-term maintenance requirements.

Manufacturing Quality & Process Control

Manufacturers with long-term industry experience understand that precision in production ensures consistent performance. Key quality control measures include:

- Precision Manufacturing: Automated cutting, molding, and finishing processes ensure precise blade dimensions and a smooth surface finish.

- Quality Checks: Each component undergoes tensile, abrasion, and impact testing to meet rigorous industrial standards.

- Batch Consistency: Consistent material properties across production batches reduce variability in cleaning efficiency and lifespan.

These controls provide engineers with the confidence that each secondary belt cleaner will perform reliably in demanding industrial conditions.

Installation & Maintenance Considerations

Proper installation and maintenance practices are essential for maximizing equipment lifespan:

- Ease of Installation: Modular designs allow for straightforward mounting without extensive conveyor modifications.

- Reduced Downtime: Secondary cleaners are engineered for quick replacement or adjustment, minimizing operational interruptions.

- Maintenance Cycles: Regular inspection of blade wear, tension, and alignment ensures continued performance and prevents unexpected failures.

In mining and metal processing operations, these practical considerations directly affect plant productivity and safety.

Safety & Operational Reliability

Secondary belt cleaners contribute to both operational reliability and worker safety:

- Worker Safety: By reducing the need for manual cleaning of residual materials, cleaners minimize worker exposure to hazardous belts and moving machinery.

- Equipment Protection: Preventing material accumulation protects pulleys, idlers, and tail sections from excessive wear or mechanical failure.

- Plant Reliability: Continuous, effective cleaning ensures steady material flow, reducing unplanned shutdowns and optimizing production schedules.

Cost Efficiency Over Equipment Life Cycle

Investing in high-quality secondary belt cleaners translates to measurable long-term benefits:

- Long-Term Savings: Reduced belt wear and maintenance interventions decrease operational expenses.

- Reduced Shutdowns: Cleaner belts prevent material buildup that can halt production.

- Maintenance Optimization: Predictable blade life allows maintenance teams to schedule replacements efficiently, improving workforce allocation and plant uptime.

Export Readiness & Global Acceptance

Industrial buyers across Asia, Africa, Europe, and the Americas expect products that meet international standards:

- Compliance with ISO and ASTM material standards.

- Documentation for material composition, hardness, and wear ratings.

- Proven track records of performance in heavy-duty environments.

Manufacturers with global exposure design secondary cleaners that meet these expectations, enabling adoption in diverse industrial contexts.

Why Experienced Manufacturers Matter

Manufacturers with long-term industry exposure understand that producing reliable secondary belt cleaners requires:

- Engineering Expertise: Knowledge of material science, wear mechanics, and conveyor systems.

- Industry Experience: Insights from decades of solving real plant-level problems.

- Reliable Supply: Consistent production ensures replacements are available, reducing downtime risk.

Such expertise separates genuine industrial-grade solutions from generic aftermarket products.

About Mouldtech Industries

Mouldtech Industries has been a trusted name in industrial wear protection and conveyor solutions across India. Serving mining companies in Odisha and Chhattisgarh, metal plants in Maharashtra and Jharkhand, cement industries in Rajasthan and Tamil Nadu, and ceramic manufacturers in Gujarat and Karnataka, Mouldtech Industries brings engineering expertise and manufacturing precision to every product.

Their portfolio includes ball mill rubber liners, ceramic wear protection tiles, rubber lining systems, ball mill rubber products, conveyor solutions, and specifically, secondary belt cleaners. Plant engineers and procurement managers rely on Mouldtech Industries for high-quality, long-lasting, and technically robust solutions.

For more details, visit their official website: https://www.mouldtechindustries.in/

Conclusion

In heavy-duty industrial environments, the secondary belt cleaner plays a pivotal role in maintaining plant efficiency, protecting conveyor systems, and ensuring worker safety. By addressing residual material buildup, these engineered solutions extend equipment lifespan, reduce maintenance frequency, and improve overall operational reliability.

Investing in well-designed secondary belt cleaners, engineered by experienced manufacturers like Mouldtech Industries, is not merely a maintenance choice—it is a strategic step toward long-term plant performance and industrial resilience.

Key Takeaways

- Provides adequate wear protection for conveyor belts and pulleys.

- Enhances operational reliability across multiple industrial sectors.

- Suitable for mining, metal, cement, ceramic, and bulk material handling industries.

- Designed for long-term performance under high-impact, abrasive, and corrosive conditions.

- Globally relevant and compliant with industrial standards for export and operational excellence.

Trending FAQs

1. What is the typical lifespan of a secondary belt cleaner?

In heavy-duty industrial environments, lifespan depends on material abrasiveness, belt speed, and operational load. With proper maintenance, rubber-based cleaners typically last 12–24 months, while hybrid designs may last longer.

2. Can secondary belt cleaners be used across all industries?

Yes. They are suitable for mining, metal processing, cement, ceramics, power plants, and bulk material handling, provided the design matches operational conditions.

3. How frequently should secondary belt cleaners be maintained?

Experienced plant engineers recommend inspection every 3–6 months, adjusting blade tension and replacing worn sections to maintain optimal cleaning efficiency.

4. When should one choose rubber over ceramic wear solutions?

Rubber blades are flexible and impact-resistant, ideal for sticky or moderately abrasive materials. Ceramic inserts are preferred for highly abrasive materials requiring extended wear resistance.

5. Are secondary belt cleaners used globally?

Yes. They are widely adopted in mining hubs of Australia and South Africa, steel and metal plants in China and India, and bulk material handling systems worldwide.

For expert guidance on Secondary Belt Cleaners, Ball Mill Rubber Liners, Ceramic Wear Protection, and Conveyor Solutions, reach out to the specialists at Mouldtech Industries.

#BallMillRubberLiner #CeramicWearProtection #RubberLining #MiningSolutions #BulkMaterialHandling #ConveyorSolutions #MouldtechIndustries #WearProtection #IndustrialManufacturing