Ball Mill Rubber Liner

- A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. The ball mill may be operated in a batch or continuous fashion, wet or dry. It is partially filled with balls.

- The grinding media is the balls which may be made of steel, stainless steel, or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber. Less wear takes place in the rubber-lined mills.

- Ball Mill Rubber Liners are always used to protect the inner shell of a cylinder from being directly impacted and worn by material and grind-balls. Besides that, the pulp in the wet grinding process corrodes the ball mill more easily.

- The Ball Mill Rubber Liner from Mouldtech protects the inner shell of the grinding mill with material and grind-balls that last longer and perform better. Our Ball Mill Rubber Liners are designed to reduce downtime and service intervals, allowing for better inventory control and lower grinding costs.

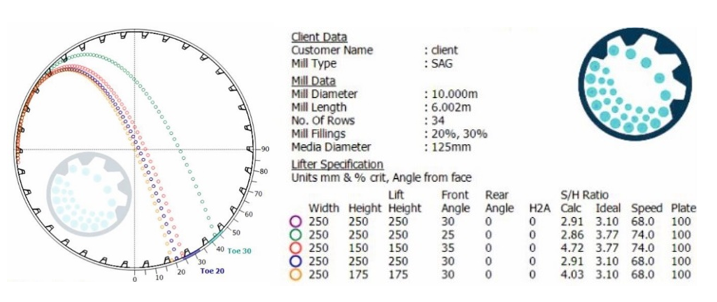

Mill Liner Design

- Poor liner design has a detrimental effect on milling performance and on liner life this results in a loss of revenue and increased operational costs. Poor milling performance can result in excess power usage and decreased recovery of the valuable minerals.

- Excess liner wear results in exorbitant liner materials costs, and excessive downtime which reduces mill availability and impacts on plant throughput. Optimised liner design can be used to strike the best economic balance between liner life and mill grinding performance, for this reason Mouldtech Industries uses computer simulation to provide optimum liner configuration that extends liner and increases Mill productivity.

Advantages of Mouldtech Mill Liners

- Customized to Suit :- Customized and perfectly fitted, Mouldtech Rubber Liners are made to increase your profits.

- Longer Wear life :-Rubber Liners from Mouldtech are pressure melded to achieve the greatest density and are designed for the best level of abrasion resistance. Industry recognized as delivering 1.5-4 times the wear life of metal liners.

- Reduced Weight Lower Costs :- Mouldtech’s Rubber Liners increase the ball mill’s energy efficiency by 15% and are 75% to 80% lighter than steel liners. less strain on the mill means less up keep.

- Easy to Install:-Light weight liners are installed quickly and easily, reducing downtime and increasing safety.

- Strong Corrosion Resistance :-The pulp in the wet grinding process more readily corrodes the ball mills. However, under a certain temperature range of 90°C to 100°C, Mouldtech rubber liners can effectively withstand the corrosion of acid and alkali materials, water, or other solutions.

- Leak Proof :-Rubber liners are fully sealed to take away any chance of slurry leakage and shell degradation.

- Reduce Noise Levels :-Favourable to the environment for safer working conditions by reducing 8 dB – 10 dB noise level.

- Easy Inventory Control :-Rubber Liner predictable wear life makes it possible to order and schedule supply in advance, thus reducing costs.

FAQs of Ball Mill Rubber Liner

Q: What is a ball mill rubber liner?

A: A ball mill rubber liner is a type of liner made from rubber that is used to protect the ball mill from wear and tear caused by grinding materials.

Q: What are the benefits of using a ball mill rubber liner?

A: The use of a ball mill rubber liner can help to reduce wear and tear on the ball mill, as well as improve the grinding efficiency of the machine. Additionally, the rubber liner can help to reduce noise levels within the ball mill.

Q: What types of materials can be ground with a ball mill rubber liner?

A: A ball mill rubber liner can be used to grind a wide range of materials, including minerals, ores, chemicals, and other materials that need to be ground into a fine powder.

Q: How long does a ball mill rubber liner typically last?

A: The lifespan of a ball mill rubber liner can vary depending on the materials being ground, the size and speed of the ball mill, and other factors. However, in general, a well-designed and well-maintained ball mill rubber liner can last for several years.

Q: How is a ball mill rubber liner installed?

A: Installing a ball mill rubber liner typically involves removing the old liner, cleaning the surface of the ball mill, and then attaching the new rubber liner using specialized adhesive or bolts.

Q: What are the maintenance requirements for a ball mill rubber liner?

A: To ensure the longevity of a ball mill rubber liner, regular maintenance is required. This may include cleaning the liner, checking for wear and tear, and making any necessary repairs or replacements.