Ceramic Embedded Rubber Liner

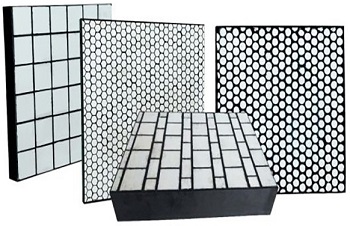

- Ceramic embedded rubber liners manufactured by Mouldtech Industries are a type of industrial liner that combines the benefits of both ceramics and rubber to provide superior protection against abrasion and impact damage. These liners consist of a rubber base with embedded ceramic tiles, offering exceptional wear resistance and durability.

Application :-

- Ceramic embedded rubber liners are widely used in industries such as mining, cement, steel, power generation, and other heavy industries. They are commonly used to line chutes, hoppers, bins, pipes, and other equipment that is exposed to abrasive materials, high impact, or chemical corrosion.

Features

- Ceramic embedded rubber liners have several features that make them an excellent choice for industrial applications. They are highly resistant to abrasion, impact, and chemical corrosion, making them suitable for use in harsh environments. The embedded ceramic tiles provide additional strength and durability to the liner, while the rubber base provides flexibility and shock absorption.

Advantages

- The use of ceramic embedded rubber liners can bring several advantages to industrial processes. For instance, it can significantly reduce maintenance costs by protecting equipment from wear and tear, thereby extending its lifespan. The embedded ceramic tiles provide additional strength and durability to the liner, reducing the need for frequent replacements. The rubber base provides flexibility and shock absorption, reducing the risk of equipment failure and downtime. Ceramic embedded rubber liners can also enhance workplace safety by reducing the risk of accidents caused by equipment failures or malfunctions.

Conclusion

- Ceramic embedded rubber liners are an excellent choice for industrial applications that require exceptional wear resistance and durability. With their unique combination of ceramic tiles and rubber base, these liners can provide long-lasting protection to equipment, reduce maintenance costs, enhance productivity, and improve workplace safety.

FAQs of Ceramic Embedded Rubber Liners

Q: What are Ceramic Embedded Rubber Liners?

A:Ceramic Embedded Rubber Liners are a type of rubber liner that has embedded ceramic tiles. They are used to protect equipment and piping in industrial applications from abrasion, impact, and erosion. The ceramic tiles provide a hard, wear-resistant surface that can withstand harsh operating conditions, while the rubber backing provides cushioning and vibration damping.

Q: What are the benefits of Ceramic Embedded Rubber Liners?

A: Ceramic Embedded Rubber Liners offer several benefits, including:

- Protection from abrasion, impact, and erosion

- Reduced maintenance costs and downtime

- Increased equipment lifespan

- Improved safety and environmental protection

- Enhanced process efficiency and productivity

- Reduced noise and vibration levels

Q: What applications are suitable for Ceramic Embedded Rubber Liners?

A:Ceramic Embedded Rubber Liners are suitable for a wide range of applications, including mining, cement, power generation, pulp and paper, steel, and chemical processing industries. They are commonly used to line chutes, hoppers, cyclones, pipes, and other equipment where abrasion and impact wear are prevalent.

Q: How are Ceramic Embedded Rubber Liners installed?

A:Ceramic Embedded Rubber Liners are typically installed using a vulcanization process, which involves bonding the rubber backing to the metal substrate using heat and pressure. The ceramic tiles are then embedded into the rubber layer using a special adhesive. Installation can be done on-site or in a workshop, depending on the size and complexity of the equipment.

Q: What factors should be considered when selecting Ceramic Embedded Rubber Liners?

A: When selecting Ceramic Embedded Rubber Liners, several factors should be considered, including:

- Operating conditions, such as temperature, pressure, and chemical exposure

- Equipment geometry and dimensions

- Material properties, including hardness, density, and abrasion resistance

- Maintenance requirements and downtime

- Cost-effectiveness and return on investment

Q: How long do Ceramic Embedded Rubber Liners last?

A:The lifespan of Ceramic Embedded Rubber Liners depends on several factors, including the operating conditions, equipment geometry, and material properties. In general, Ceramic Embedded Rubber Liners can last several years before needing replacement or maintenance, depending on the severity of the wear and tear.

Q: How can I maintain Ceramic Embedded Rubber Liners?

A: Maintaining Ceramic Embedded Rubber Liners involves regular inspections and cleaning to remove any debris or buildup that may affect their performance. It is also important to monitor wear patterns and replace any damaged or worn components as needed. Proper handling and storage can also help extend the lifespan of Ceramic Embedded Rubber Liners.