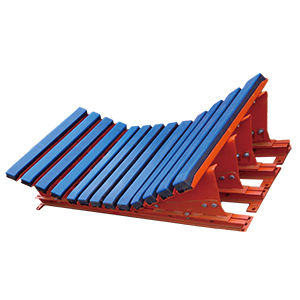

Impact Bar

- An Impact Bar is a type of equipment that is commonly used in material handling industries to protect conveyor belts, equipment, and structures from the impact of heavy loads. When heavy materials are transferred through a conveyor system, they can generate significant force, which can cause damage to the conveyor belt and other equipment. Impact Bars are designed to absorb and distribute the force of the impact, reducing the risk of damage.

- Mouldtech Industries can manufacture Impact Bars from a variety of materials, including rubber, polyurethane, and ceramic. They are typically installed at the transfer points along the conveyor system, where materials are loaded and unloaded. When a heavy load strikes the Impact bar, it compresses, distributing the force across the pad and reducing the impact on the conveyor belt.

The benefits of using Impact Bars

- Reduce downtime and maintenance cost.

- Extend equipment life.

- Improve safety.

- Prevent damage to conveyor belts and other equipment.

- In addition, the use of Impact Bars can improve safety in material handling facilities by reducing the risk of equipment failure and accidents. When heavy loads strike a conveyor belt or other equipment, it can create dangerous conditions for workers, such as flying debris or equipment malfunction. By minimizing the impact of heavy loads, Impact Bars help to create a safer work environment for employees.

- Overall, Impact Bars are an important component of material handling systems in many industries. By absorbing and distributing the force of heavy loads, they help to protect equipment, reduce maintenance costs, and improve safety.

FAQs About Impact Bar

Q: What is an Impact Bar?

A:An Impact Bar is a mechanical component that is typically installed on conveyor belts or other material handling equipment. It is designed to absorb and distribute impact forces, thereby reducing damage to the conveyor belt and other components.

Q: What are the benefits of using Impact Bars?

A:The primary benefit of using Impact Bars is that they reduce damage to conveyor belts and other equipment, which can lead to reduced downtime, lower maintenance costs, and increased productivity. Additionally, Impact Bars can help to reduce noise levels, which can improve the working environment for employees.

Q: What materials are Impact Bars made from?

A:Impact Bars are typically made from a combination of rubber and metal, with the rubber serving as the impact-absorbing component and the metal providing structural support.

Q: How are Impact Bars installed?

A:Impact Bars are typically installed by being bolted or welded onto the conveyor frame. The exact installation method will depend on the specific type of Impact Bar and the conveyor system being used.

Q: What types of Impact Bars are available?

A:There are many different types of Impact Bars available, including standard Impact Bars, low-friction Impact Bars, anti-static Impact Bars, and more. The specific type of Impact Bar that is best for a particular application will depend on factors such as the type of material being transported, the conveyor speed, and the level of impact force involved.

Q: Where can I purchase Impact Bars?

A:Impact Bars can be purchased from a variety of industrial suppliers and distributors. It is important to choose a reputable supplier who can provide high-quality Impact Bars that are designed to meet the specific needs of your application.