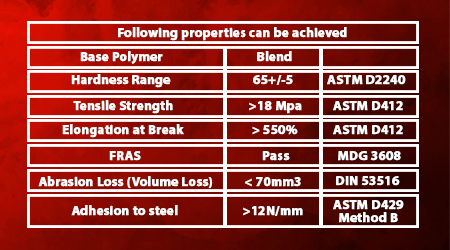

- Cold vulcanized rubber pulley lagging – FRAS manufacture by Mouldtech Industries is a specialized type of protective layer of rubber that is applied to the surface of a conveyor pulley. This layer is designed to increase the friction between the pulley and the conveyor belt, thereby improving the overall performance of the conveyor system. Cold vulcanized rubber pulley lagging – FRAS is also flame retardant and anti-static, making it suitable for use in hazardous environments.

Features

- Cold vulcanized rubber pulley lagging – FRAS is available in a range of thicknesses, from 6mm to 25mm, to suit a variety of conveyor applications. It is also available in a range of patterns, including diamond, herringbone, and plain, which are designed to provide optimal grip and traction. In addition, it is flame retardant and anti-static, which makes it suitable for use in hazardous environments.

Applications

- Cold vulcanized rubber pulley lagging – FRAS is used in a variety of industries, including mining, oil and gas, and chemical processing. It is typically used in conveyor systems that operate in hazardous environments where flame retardancy and anti-static properties are required. It is also used in conveyor systems that handle abrasive materials, such as gravel, sand, and coal.

Advantages

There are many advantages to using cold vulcanized rubber pulley lagging – FRAS. These include:

- Flame retardancy: The FRAS properties of the rubber layer make it resistant to flames, which reduces the risk of fires in hazardous environments.

- Anti-static properties: The anti-static properties of the rubber layer reduce the risk of static electricity buildup, which can cause sparks and fires in hazardous environments.

- Increased friction: The rubber layer provides increased friction between the pulley and the belt, which improves the overall performance of the conveyor system.

- Extended belt life: The rubber layer also protects the belt from wear and tear, which extends its lifespan.

- Improved safety: The improved grip and traction provided by the rubber layer reduces the risk of belt slippage, which can cause accidents and damage to equipment.

- Easy installation: Cold vulcanized rubber pulley lagging – FRAS is easy to install and can be applied on site, without the need for specialized equipment or expertise.

- Cost-effective: Compared to other types of pulley lagging, cold vulcanized rubber pulley lagging – FRAS is a cost-effective solution that provides excellent performance and durability in hazardous environments.