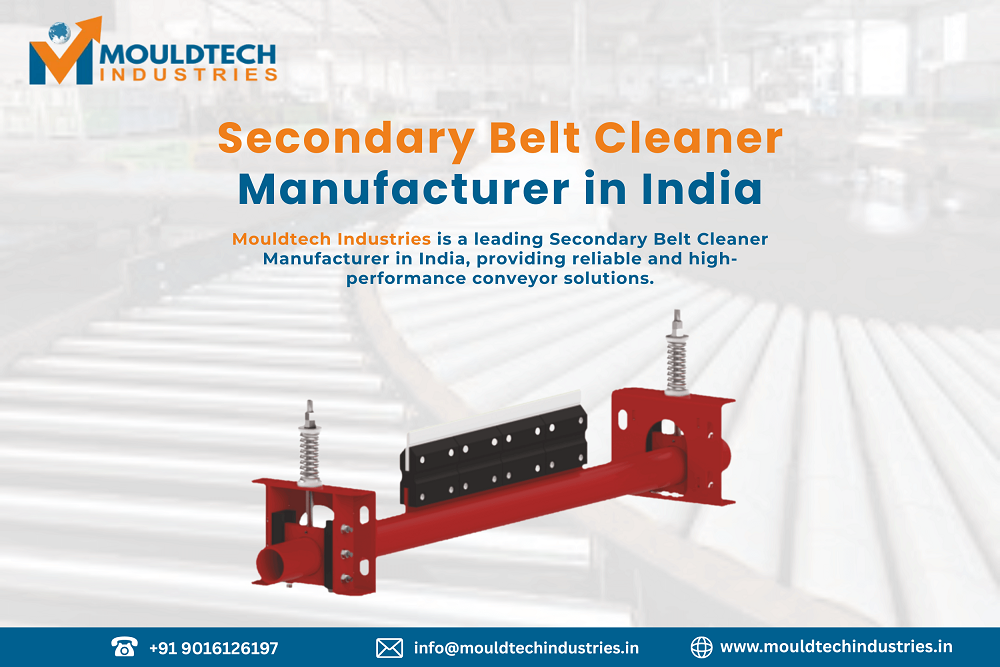

India’s Reliable Secondary Belt Cleaner Manufacturer for Conveyor Systems: Mouldtech Industries Pvt. Ltd.

In heavy-duty industrial environments such as mining, cement manufacturing, metal processing, ceramics, and bulk material handling, conveyor systems form the backbone of material movement. As a Secondary Belt Cleaner Manufacturer in India, the focus remains on supporting conveyors that handle iron ore in mining pits, clinker in cement plants, coal in power stations, and raw materials in ceramic production—applications where equipment operates continuously under harsh mechanical stress and challenging environmental conditions, demanding reliable and efficient belt cleaning solutions.

Around the world, industries face growing pressure to improve operational reliability while managing maintenance costs. Throughout industrial sectors across India—including all regions such as Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal, and all Union Territories—facilities are prioritizing proactive wear defense over fixing problems after they happen.

A vital yet sometimes overlooked element for achieving cleaner, safer, and more dependable conveyor running is the Secondary Belt Cleaner. When properly engineered and deployed, it plays a crucial role in reducing material left behind, safeguarding equipment further down the line, and maintaining plant operational time.

Industrial Issues Driving Demand for Secondary Belt Cleaners

Seasoned plant engineers often note that most conveyor-related malfunctions stem not from the belt itself, but from material build up and uncontrolled wear.

Main issues include:

- Surface Grinding: Fine and coarse material abrades belt surfaces, pulleys, and structural elements.

- Load Impacts: Heavy lump sizes lead to uneven wear and stress points.

- Deterioration: Moisture, chemicals, and slurry environments speed up component breakdown.

- Unscheduled Stops: Material carryover, belt running off-track, chute blockages, and emergency shutdowns.

- Growing Upkeep Expenditures: Frequent manual cleaning increases worker exposure and reduces machine uptime.

In mining and metal-shaping operations across India’s iron ore zones, coal deposits, limestone quarries, ceramic hubs, and major ports, these difficulties are compounded by continuous operations and high material volumes. Globally, similar conditions exist in resource-rich areas and industrial corridors, making efficient belt cleaning systems a universal necessity.

Understanding the Secondary Belt Cleaner

A Secondary Belt Cleaner is positioned after the central cleaner, usually on the return half of the conveyor belt. Its job isn’t to substitute the primary cleaner but to sweep away leftover material still clinging to the belt after initial cleaning.

From an engineering viewpoint, secondary cleaners target fine carryback particles that primary setups miss. If these particles are ignored, they build up on return idlers, pulleys, and the conveyor frame.

A well-conceived secondary belt cleaner maintains a steady contact force on the belt, adapts to belt wear over time, and operates reliably under fluctuating loads without damaging the belt surface.

Uses Across Various Sectors

Secondary belt cleaners are utilized anywhere conveyors operate under constant or heavy-duty conditions.

- Mining Sector: Employed in iron ore, coal, bauxite, and mineral processing sites to manage carryback and lessen debris along extended conveyor routes.

- Cement Facilities: Essential for limestone, clinker, and additive conveyors where fine material buildup can quickly impact belt alignment and pulley performance.

- Metal & Steel Mills: Applied in sinter plants, furnace feed conveyors, slag handling setups, and raw material depots.

- Ceramic Production: Crucial in handling raw ceramic materials, particularly where fine powders and abrasive minerals are moved.

- Power Generation Sites: Used in coal handling plants to minimize dust creation and boost operational neatness.

- Bulk Material Management: Ports, storage yards, and logistics hubs that handle aggregates, fertilizers, and minerals depend on secondary cleaners for consistent operations.

Material Science & Design Aspects

Producers with extensive industry experience know that belt cleaner performance greatly relies on material selection.

- Rubber Characteristics

- Flexibility for continuous belt contact

- Resistance to scraping and tearing

- Capacity to absorb shocks without breaking

- Ceramic Toughness

Design & Customization Needs

No two conveyor systems are identical. Effective secondary belt cleaners require:

- Suitability for Belt Width and Velocity

- Tailored Sizing for Conveyor Structure

- Adaptation to Material Properties

- Mounting Style Based on Available Space

Design specific to the plant ensures the cleaner maintains ideal contact without overburdening the belt or support structure.

Manufacturing Excellence & Process Control

Accurate manufacturing is key for industrial wear components.

Key quality factors include:

- Precise dimensions of scrapers and mounting units

- Controlled rubber and ceramic makeup

- Consistent joining techniques

- Traceability and inspection of each batch

Reputable producers adhere to structured quality checks to guarantee uniform performance across installations.

Setup & Servicing Needs

From a maintenance perspective, secondary belt cleaners should:

- Permit simple fitting without major conveyor changes

- Allow for fast scraper replacement

- Demand minimal adjustments during usage

Less frequent maintenance involvement directly leads to reduced downtime and better plant availability.

Safety & Operational Trustworthiness

Safety is a top priority in industrial work.

Secondary belt cleaners help by:

- Lowering the need for manual cleaning exposure

- Minimizing spills and trip risks

- Protecting rollers and pulleys from material accumulation

Cleaner conveyor surroundings lead to safer work environments and improved compliance with rules.

Value Over the Equipment’s Service Life

Although pricing differs by use case, the long-term advantages are steady:

- Fewer unexpected stoppages

- Longer belt and pulley service life

- Reduced maintenance labour effort

- Smoother production continuity

Life-cycle value, rather than initial outlay, is the primary measure for experienced operational teams.

Readiness for Export & Global Acceptance

Industrial purchasers in worldwide markets anticipate:

- Consistent manufacturing quality

- Technical documents and blueprints

- Awareness of international operational benchmarks

- Dependable delivery schedules

Secondary belt cleaners intended for export must meet these expectations to succeed in varied industrial settings.

Why Experienced Producers Are Important?

Manufacturers with years of industrial experience grasp real-world plant scenarios—beyond theoretical performance.

They provide:

- Engineering driven by application needs

- Tested material compositions

- Reliable post-sale support

- Steady long-term supply

- Such skill directly impacts operational success.

About Mouldtech Industries

Mouldtech Industries is a seasoned industrial producer specializing in ball mill rubber linings, ceramic wear-defence systems, rubber cladding systems, rubber products for ball mills, and conveyor solutions, serving clients across India and international industrial arenas.

With deep insight into mining, cement, metal, ceramic, and bulk material transport applications, the firm focuses on practical engineering, material performance, and manufacturing uniformity.

More data is at 👉 https://www.mouldtechindustries.in/

Summary

Secondary belt cleaners play a vital role in maintaining conveyor efficiency, protecting machinery, and enhancing operational safety. When correctly designed and implemented with plant-specific knowledge, they contribute significantly to lasting dependability in challenging industrial settings.

For operations teams, investing in established wear protection solutions is not about fast returns—it is about maintaining performance throughout the entire equipment service period.

Key Takeaways

- Minimizes material carryback and scattered debris

- Boosts conveyor system dependability

- Suitable for mining, cement, metal, ceramic, and power sectors

- Improves safety and maintenance efficiency

- Offers lasting operational worth

QUICK ANSWERS

1. What is the typical operational duration of a secondary belt cleaner?

- Service life depends on material abrasiveness, belt velocity, and running hours. Choosing the right material significantly extends its proper time.

2. Can these cleaners be fitted to existing conveyor lines?

- Yes, most setups are designed for later integration with minimal structural alteration.

3. How frequently requires servicing or adjustment?

- Routine check intervals differ by use, but modern designs need minimal tinkering.

4. Rubber or ceramic cleaners—how to decide?

- Rubber offers pliability and impact cushioning, whereas ceramic delivers superior wear resistance in strict settings.

#BallMillRubberLiner #SecondaryBeltCleaner #RubberLining #MiningSolutions #BulkMaterialHandling #ConveyorSolutions #MouldtechIndustries #WearProtection #IndustrialManufacturing