Mouldtech Industries Pvt. Ltd.: Precision Diamond Groove Sheet Manufacturer in India

Industries like mining, metal processing, cement manufacturing, ceramics, and bulk material handling operate under some of the harshest mechanical conditions in any industrial environment. Continuous material movement, high-impact loads, abrasive minerals, chemical exposure, and round-the-clock production schedules place enormous stress on equipment surfaces. To withstand these challenges, choosing a reliable Diamond Groove Sheet Manufacturer in India ensures durable, high-performance sheets that enhance equipment longevity, reduce wear, and maintain operational efficiency in demanding industrial settings.

In demanding industrial settings, unprotected contact surfaces are often the weakest link in the workflow. Wear-related failures result in frequent stoppages, safety hazards, increased maintenance costs, and inconsistent output quality. As worldwide demand for minerals, steel, cement, and ceramics continues to grow, plants face pressure to improve reliability while managing overall costs.

This trend has spurred the broader use of specialized wear-defense systems like Diamond Groove Sheet, which plays an integral role in prolonging equipment life, improving footing, and reducing operational risks in harsh plant settings.

Industrial Issues Prompting Demand for Diamond Groove Sheet

Seasoned plant managers often note that most unscheduled halts stem from expected wear patterns rather than sudden breakdowns. Common issues include:

- Abrasion: In ore extraction and material conveyance setups, continuous exposure to ore, clinker, aggregates, and mineral feedstocks causes surface erosion. Over time, this cuts equipment performance and jeopardizes safety.

- Impact Forces: Transfer points, chutes, hoppers, and lining zones are repeatedly subjected to heavy blows from falling or sliding materials, accelerating surface deterioration.

- Chemical Deterioration & Environmental Exposure: Water, chemicals, and temperature shifts in cement works, power stations, and mineral processing units contribute to material breakdown.

- Outages & Repair Expenses: Frequent liner replacements increase downtime, labor requirements, and operational interruptions—especially in high-capacity facilities operating across India and major global industrial centers.

These difficulties are not unique to one location. Similar circumstances are seen in the mining belts of India, steel complexes, ceramic production areas, and bulk-handling docks worldwide.

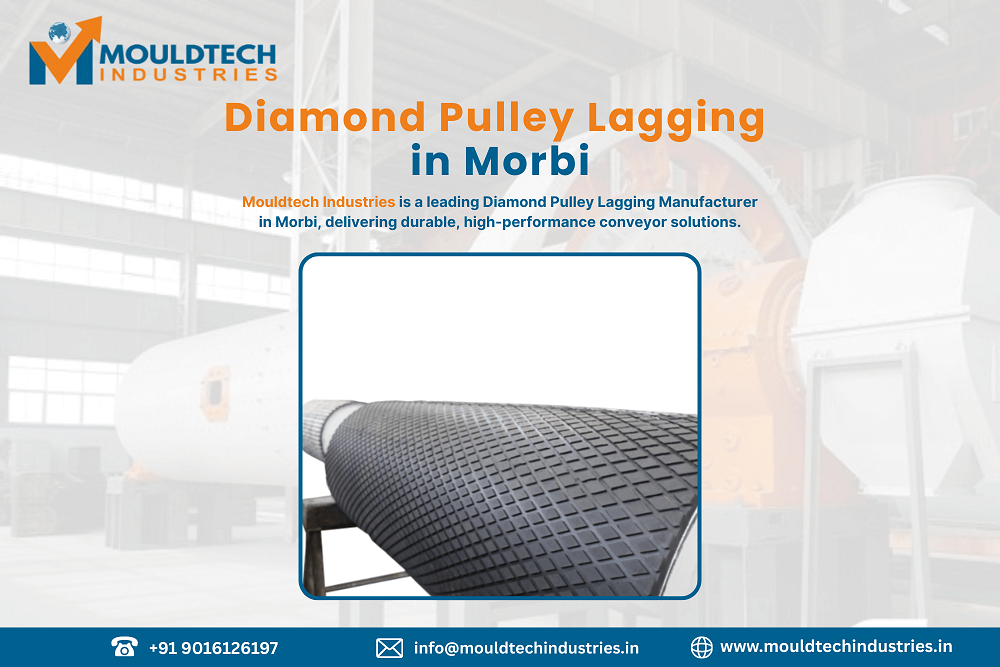

What is Diamond Groove Sheet?

Diamond Groove Sheet is a purpose-built rubber industrial sheeting with a diamond-textured surface. The groove structure boosts grip, evens out load distribution, and provides controlled material loss in high-friction settings.

In contrast to flat rubber sheets, the diamond groove design helps to:

- Improve grip even when damp or dusty

- Spread mechanical stress more evenly

- Decrease surface sliding and material buildup

It is generally employed as a protective and functional surface covering in areas exposed to rubbing, shaking, and movement of people or materials. Notably, it is not meant to replace every wear solution but serves as a supporting element within complete lining and protection setups.

Uses Across Various Sectors

Mining Sector: Utilized on walkways, platforms, transition points, and lining surfaces where slip resistance and surface toughness are vital.

- Cement Factories: Applied in material conveyance zones, maintenance access spots, and auxiliary machinery where erosion and dust are constant issues.

- Metal & Steel Works: Aids safer operations near kilns, rolling stations, and material transfer lines by improving traction and surface resilience.

- Ceramic Production: In facilities that handle raw minerals and finished tiles, Diamond Groove Sheets help manage abrasive dust and material pathways.

- Power Generation: Employed in coal handling areas, ash disposal zones, and service platforms subject to heat, dust, and vibration.

- Bulk Material Handling: Broadly used in conveyor systems, loading docks, ports, and warehouses, moving minerals, grains, and industrial commodities.

Material Science & Engineering Aspects

Manufacturers with extensive industry background recognize that material choice dictates real-world results.

Rubber Qualities

Industrial-grade rubber mixes in Diamond Groove Sheets are chosen for their:

- Resistance to scraping wear

- Flexibility for absorbing shocks

- Durability against environmental aging

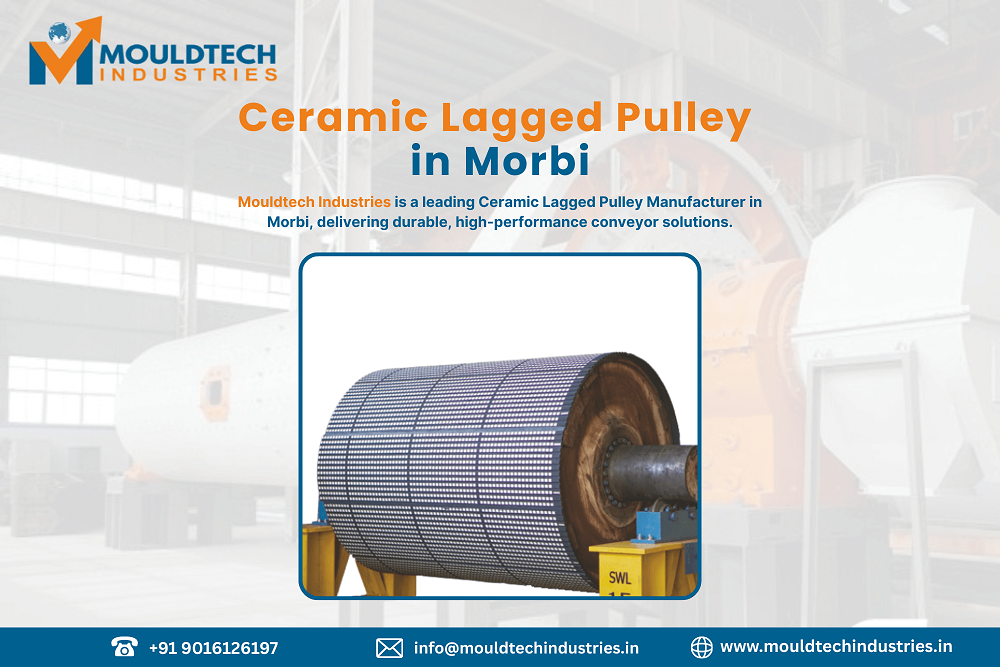

- Ceramic Versus Rubber Wear Performance

While ceramic wear defenses target maximum scraping resistance, rubber-based options excel at shock absorption and vibration dampening. In many applications, rubber parts reduce noise and structural strain.

Design & Customization Needs

Every facility layout differs. Effective Diamond Groove Sheet performance relies on correct design and application.

Key factors include:

- Shape of the equipment and surface adaptability

- Thickness selection based on load and impact level

- Precise cutting for platforms, chutes, or floor areas

- Integration with existing rubber lining systems or conveyor setups

Tailoring ensures the sheet performs its intended function without hindering adjacent machinery.

Manufacturing Excellence & Process Control

Uniformity is essential for industrial wear items. Precise manufacturing methods guarantee:

Uniform groove depth and pattern precision

Consistent rubber compound characteristics between batches

Controlled vulcanization for predictable physical traits

Quality checks generally involve measuring dimensions, testing hardness, and visually assessing the surface to confirm reliability from batch to batch.

Mounting & Upkeep Notes

From a maintenance viewpoint, Diamond Groove Sheets are valued for:

- Simple mounting utilizing mechanical fasteners or glues

- Minimal alteration to current structures

- Predictable wear patterns that streamline checks

Reduced setup complexity helps upkeep teams finalize work during scheduled off-times, limiting production losses.

Safety & Operational Dependability

Slippery surfaces remain a primary safety worry in industrial plants. Diamond Groove Sheets enhance:

- Worker grip in wet, dusty, or greasy conditions

- Protection of equipment surfaces from wear-related failure

- Overall operational stability by slowing surface deterioration

In mineral extraction and metal processing activities, better surface stability directly promotes safer working settings.

Financial Efficiency Across Equipment Lifespan

Instead of focusing solely on initial material costs, experienced operations teams assess solutions across the entire equipment life cycle.

Advantages include:

- Longer service periods

- Fewer unplanned stops

- Reduced need for replacement

- Streamlined maintenance scheduling

These elements lead to noticeable long-term savings without sacrificing operational capability.

Export Readiness & Global Acceptance

Industrial buyers in worldwide markets anticipate:

- Uniform quality documentation

- Standardized production methods

- Clear technical specifications

- Dependable supply schedules

Wear defense goods intended for export must align with international industrial benchmarks, particularly for mining centers, cement works, and ceramic clusters everywhere.

Why Proven Manufacturers Matter?

Choosing a wear antidote is an engineering choice, not just a product selection.

Manufacturers with confirmed industry history:

- Grasp real-world facility issues

- Suggest solutions tailored to the specific use

- Maintain uniform quality over extended supplies

Effectively support Original Equipment Manufacturers, Engineering, Procurement, and Construction contractors, and plant engineers.

Expertise mitigates risk and enhances operational results.

About Mouldtech Industries

Mouldtech Industries is an established industrial producer concentrating on wear defense solutions, including Ball Mill Rubber Liners, Ceramic Wear Protection Solutions, Rubber Lining Systems, Ball Mill Rubber Products, Conveyor Solutions, and Diamond Groove Sheets.

Serving Indian industrial markets—including Maharashtra (Mumbai, Pune, Nagpur), Gujarat (Ahmedabad, Surat, Vadodara, Rajkot), Rajasthan (Jaipur, Udaipur), Odisha (Keonjhar, Rourkela), Chhattisgarh (Raipur, Bhilai), Jharkhand (Ranchi, Dhanbad), West Bengal (Durgapur, Asansol), Tamil Nadu (Chennai, Coimbatore, Salem), Karnataka (Bengaluru, Bellary), Andhra Pradesh (Visakhapatnam), Telangana (Hyderabad), Madhya Pradesh (Indore), Uttar Pradesh (Noida), Haryana (Faridabad), Punjab (Ludhiana), and other industrial towns across all Indian states—Mouldtech Industries also supports global industrial needs.

Discover more at 👉 https://www.mouldtechindustries.in/

In Summary:

Diamond Groove Sheet is a practical, engineered solution that addresses genuine issues of wear, safety, and reliability in heavy industrial settings. When correctly designed, manufactured, and fitted, it aids in better plant function, safer operations, and managed upkeep schedules.

For sectors seeking enduring operational dependability over temporary fixes, appropriately engineered wear protection remains a vital investment.

Key Takeaways

- Effective wear defense lessens downtime and upkeep demands

- Diamond Groove Sheet improves grip and surface toughness

- Appropriate for mining, cement, metal, ceramic, and bulk handling sectors

- Supports safer work settings

- Delivers long-term performance in challenging industrial situations

FAQs

Q1. What is the typical service duration of a Diamond Groove Sheet?

- Service duration varies based on wear intensity, load conditions, and maintenance practices. In managed settings, it offers consistent service across longer periods.

Q2. Is Diamond Groove Sheet suitable for high-impact areas?

- Yes, rubber-based sheets are better at absorbing impact energy than rigid materials, making them appropriate for zones with varied wear.

Q3. How often should maintenance checks occur?

- Inspection frequency corresponds with facility shutdown plans and operating conditions, usually during routine maintenance checks.

Q4. How does rubber wear protection compare to ceramic options?

- Rubber offers shock absorption and flexibility, while ceramic provides extreme resistance to scraping. Selection hinges on the specific use case.

#BallMillRubberLiner #SecondaryBeltCleaner #RubberLining #MiningSolutions #BulkMaterialHandling #ConveyorSolutions #MouldtechIndustries #WearProtection #IndustrialManufacturing