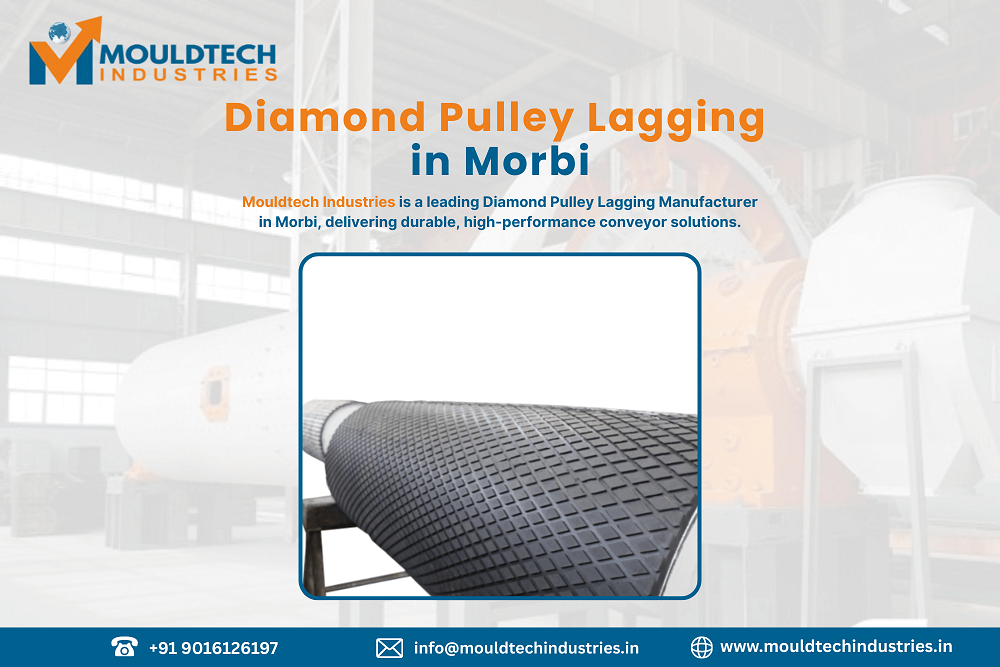

Diamond Pulley Lagging Manufacturer, Supplier, And Exporter in India: Mouldtech Industries

Mouldtech Industries is a Manufacturer of Diamond Pulley Lagging in Morbi.

Our Manufacturing Unit is in Vadodara, Gujarat, India.

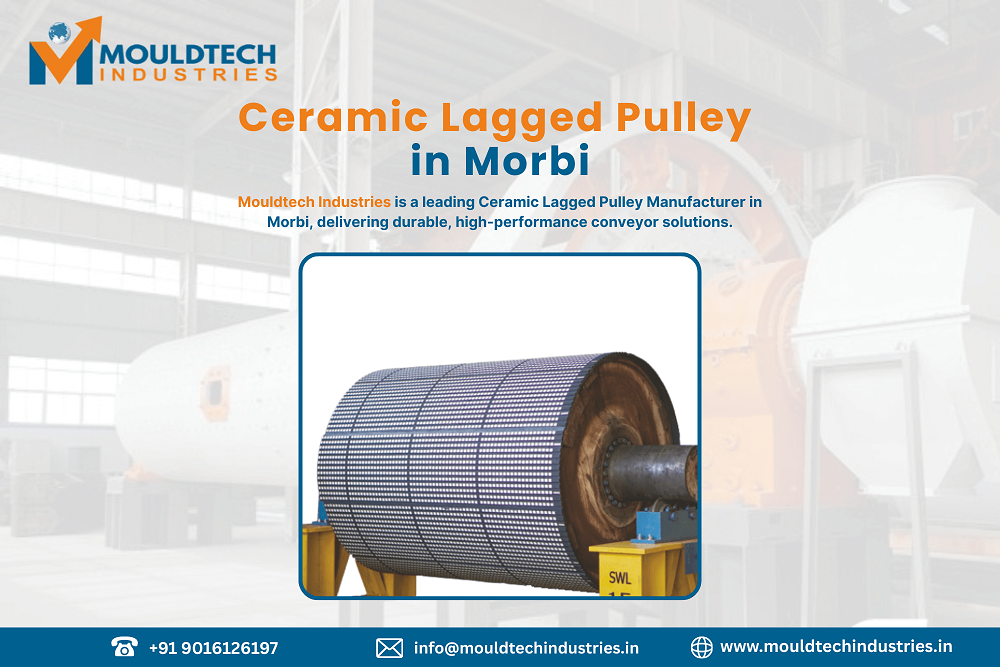

Mouldtech Industries is a Manufacturer of Bridge Rubber Pad, Ball Mill Rubber Lining, Bridge Rubber Pad, Resistant Rubber Liner, Embedded Rubber Liners, Conveyors Solutions, Ceramic Lagging Sheet, Belt Cleaners, Bridge Rubber Pad, Ceramic Rubber Lagging Services, and Ceramic Rubber Lagging Sheet.

Enhancing Industrial Efficiency with Diamond Pulley Lagging

Introduction

In heavy-duty industrial environments such as mining, metal processing, cement production, ceramics manufacturing, and bulk material handling, equipment reliability is non-negotiable. Plants operate under extreme abrasion, impact loads, and corrosive conditions, where even minor downtime can result in significant production losses. Experienced plant engineers often observe that much of the operational cost stems not from the raw equipment but from wear-related maintenance and unplanned stoppages.

In this context, wear protection solutions become a critical factor in sustaining continuous operations. Globally, industries are increasingly investing in high-performance materials and engineered solutions that can withstand harsh operating conditions. Among these, Diamond Pulley Lagging has emerged as a practical and reliable solution for extending pulley life, improving belt grip, and reducing maintenance interventions.

Industrial Challenges That Drive Demand for Diamond Pulley Lagging

Industries across India and global markets face several recurring challenges that demand durable pulley protection:

- Abrasion: Pulley surfaces in conveyor systems are constantly exposed to abrasive materials like iron ore, cement clinker, coal, and ceramic powders. Over time, this abrasion reduces pulley diameter, affects belt alignment, and increases slippage risks.

- Impact Loads: Heavy lumps or misaligned material can exert sudden impact on pulleys. Without proper lagging, this can lead to structural damage or excessive wear on belts, impacting operational continuity.

- Corrosion: In cement plants, chemical reactions and moisture can corrode metal pulley surfaces, reducing their functional life. Similarly, in metal and steel plants, acidic by-products or mineral dust can accelerate degradation.

- Downtime: Unplanned shutdowns for pulley replacement or maintenance disrupt production schedules, often resulting in high financial and operational losses.

- Maintenance Cost: Frequent pulley replacements, rubber repairs, or belt adjustments increase labor, materials, and maintenance overheads. Experienced engineers recognize that these costs can escalate quickly in continuous operation plants.

In mining and metal processing operations, these challenges are compounded by environmental factors such as temperature fluctuations, humidity, and dust exposure. Manufacturers with long-term industry exposure understand that proactive wear solutions like Diamond Pulley Lagging are essential to maintaining reliable plant operations.

What Is Diamond Pulley Lagging?

Diamond Pulley Lagging is an engineered rubber lining system designed to protect pulleys in conveyor applications. Unlike conventional rubber or bare metal pulleys, diamond lagging features a patterned surface — typically a diamond or chevron profile — that:

- Increases friction between the belt and pulley, minimizing slippage

- Provides uniform wear resistance across the pulley face

- Absorbs impact loads from falling material

- Reduces belt vibration and misalignment

In industrial terms, this solution is not a quick-fix. It is a wear protection strategy aimed at extending pulley life, improving conveyor efficiency, and ensuring operational safety in demanding environments.

Applications Across Industries

Diamond Pulley Lagging finds utility across multiple industrial sectors in India and globally:

- Mining: In iron ore, coal, and bauxite mining, pulleys face high abrasion and heavy impact loads. Lagging ensures belt grip under variable material flow conditions, reducing slippage and maintenance interventions.

- Cement: Cement plants handle abrasive clinker and raw materials with high silica content. Diamond Pulley Lagging protects pulleys from surface degradation and minimizes downtime during heavy production cycles.

- Metal & Steel: In steel and metal plants, pulleys convey hot billets, ore concentrates, or slag. Lagging safeguards equipment from abrasive and high-temperature wear, improving operational continuity.

- Ceramic Manufacturing: Ceramic raw materials like kaolin and feldspar are highly abrasive. Lagging ensures long-term pulley protection in tile and sanitary ware production lines.

- Power Plants & Bulk Material Handling: Pulley lagging in coal and biomass conveyor systems prevents slippage, improves traction, and enhances worker safety while reducing maintenance frequency.

In all these applications, plant engineers in India’s industrial hubs — including Maharashtra, Gujarat, Chhattisgarh, Odisha, Tamil Nadu, Karnataka, Andhra Pradesh, and Rajasthan — report measurable improvements in conveyor efficiency and reduced equipment failures after installing diamond pulley solutions.

Material Science & Engineering Considerations

The performance of Diamond Pulley Lagging depends heavily on material engineering:

- Rubber Properties: High-quality natural or synthetic rubber provides elasticity, impact absorption, and thermal stability. Shore hardness is selected based on material load and operating temperature.

- Ceramic Hardness (if embedded): Certain high-wear applications integrate ceramic inserts to resist extreme abrasion. Proper bonding ensures durability without compromising flexibility.

- Wear Resistance Principles: The diamond or chevron pattern distributes wear uniformly, preventing localized damage and extending service life.

- Impact Absorption: Lagging materials cushion pulleys from sudden impacts, protecting both belts and drive components.

Experienced engineers emphasize that understanding material properties is critical for selecting the right lagging for a given industrial environment.

Design & Customization Requirements

Diamond Pulley Lagging is not one-size-fits-all. Effective implementation requires:

- Equipment Compatibility: Pulley diameter, width, and drive speed must be factored in.

- Custom Sizing: Tailored dimensions ensure full coverage and proper fitment.

- Application-Specific Design: Pattern type, rubber hardness, and embedded ceramic positioning are selected based on material characteristics and operational load.

Manufacturing Quality & Process Control

Reliable Diamond Pulley Lagging depends on precision manufacturing and rigorous quality control:

- Precision Manufacturing: Ensures dimensional accuracy and consistent pattern depth.

- Quality Checks: Adhesion strength, Shore hardness, and wear testing confirm long-term performance.

- Batch Consistency: Uniformity across production batches prevents operational discrepancies in multi-pulley systems.

Manufacturers with long-term industry exposure recognize that these factors determine not only product life but also plant reliability.

Installation & Maintenance Considerations

Proper installation and maintenance significantly impact the effectiveness of pulley lagging:

- Ease of Installation: Modular designs and pre-cured sheets reduce installation time.

- Reduced Downtime: Quick installation minimizes operational interruptions.

- Maintenance Cycles: Regular inspections for wear and bonding integrity prevent unforeseen failures.

Experienced plant engineers often observe that even high-quality lagging fails if installation protocols are ignored.

Safety & Operational Reliability

Diamond Pulley Lagging enhances both safety and operational reliability:

- Worker Safety: Reduced belt slippage and misalignment decrease the risk of conveyor accidents.

- Equipment Protection: Pulley and belt life are extended, lowering the risk of mechanical failure.

- Plant Reliability: Continuous operation without unscheduled shutdowns improves overall productivity.

Cost Efficiency Over Equipment Life Cycle

Though upfront investment may be higher than standard pulleys, lagging provides long-term financial benefits:

- Long-Term Savings: Reduced pulley replacements and extended belt life lower operating costs.

- Reduced Shutdowns: Minimized downtime directly translates to production continuity.

- Maintenance Optimization: Less frequent repairs save labor, parts, and unplanned intervention costs.

Export Readiness & Global Acceptance

Industrial buyers globally expect compliance with quality standards and documented performance:

- Standards Awareness: ISO and other industrial certifications are increasingly demanded for export.

- Documentation: Material datasheets, wear test results, and installation guidelines support global sales.

- Global Buyer Requirements: Buyers in mining hubs such as Australia, South Africa, and Latin America prefer lagging solutions with proven industrial reliability.

Why Experienced Manufacturers Matter

Partnering with experienced manufacturers ensures engineering precision and dependable supply:

- Engineering Expertise: Material selection, pattern design, and application recommendations are informed by decades of field experience.

- Industry Experience: Long-term exposure to mining, cement, and bulk handling environments allows manufacturers to anticipate wear challenges.

- Reliable Supply: Consistent quality and timely delivery prevent production delays and unplanned downtime.

About Mouldtech Industries

Mouldtech Industries is a trusted manufacturer of industrial wear protection solutions, including Diamond Pulley Lagging, serving both Indian and international markets. With extensive experience in rubber lining systems, ball mill rubber products, ceramic wear protection, and conveyor solutions, Mouldtech Industries collaborates with mining companies, cement plants, metal & steel producers, and bulk material handlers to provide engineered, high-reliability solutions. Learn more at their official website: https://www.mouldtechindustries.in/

Conclusion

In heavy-duty industrial environments, Diamond Pulley Lagging plays a crucial role in protecting pulleys, improving belt grip, and minimizing downtime. For plant engineers and operations teams, selecting the right lagging material and design enhances reliability, reduces maintenance frequency, and optimizes overall equipment life. Manufacturers with proven industrial expertise, such as Mouldtech Industries, provide solutions aligned with both Indian and global industrial standards, ensuring consistent operational efficiency.

Key Takeaways

- Provides effective wear protection for pulleys and conveyor belts

- Enhances operational reliability and safety in heavy-duty plants

- Suitable for mining, metal, cement, ceramic, and bulk material handling industries

- Offers long-term performance and reduced maintenance costs

- Recognized in both Indian and global industrial markets

Trending FAQs

Q1. What is the expected lifespan of Diamond Pulley Lagging?

A1. Depending on operational conditions and material type, it typically lasts 3–7 years in mining and bulk handling operations.

Q2. Which industries are best suited for Diamond Pulley Lagging?

A2. Mining, cement, steel, metal processing, ceramics, power plants, and bulk material handling industries benefit most.

Q3. How often should pulley lagging be inspected or maintained?

A3. Experienced engineers recommend visual inspections every 6–12 months, with minor maintenance as needed to prevent unplanned downtime.

Q4. When should I choose rubber over ceramic wear solutions?

A4. Rubber is preferred for impact absorption and belt grip, while ceramic is selected for extreme abrasion resistance. Hybrid solutions are possible.

Q5. Is Diamond Pulley Lagging used globally?

A5. Yes, mining hubs in Australia, South Africa, and Latin America, as well as bulk handling plants worldwide, regularly use these solutions.

For expert solutions on Diamond Pulley Lagging and industrial wear protection, contact Mouldtech Industries today. Visit our website or reach out to discuss your plant requirements.

#DiamondPulleyLagging #BallMillRubberLiner #CeramicWearProtection #RubberLining #ConveyorSolutions #MiningSolutions #BulkMaterialHandling #MouldtechIndustries #WearProtection #IndustrialManufacturing