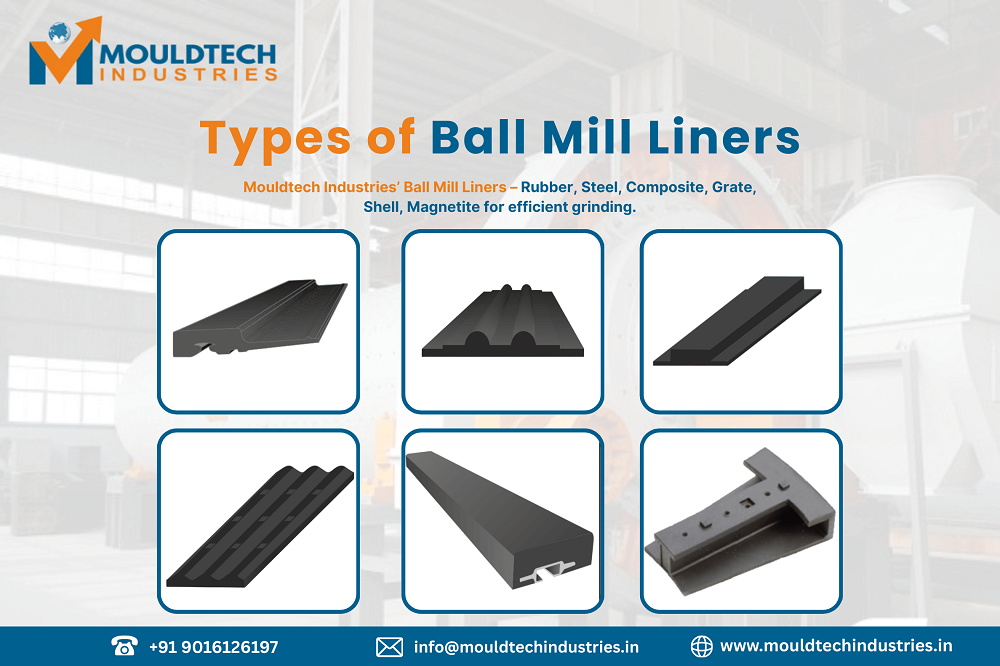

Types of Ball Mill Liners Manufacturer in India: Mouldtech Industries

Mouldtech Industries is a Manufacturer, Supplier, and Exporter of Types of Ball Mill Liners.

Our Manufacturing Unit is in Vadodara, Gujarat, India.

Mouldtech Industries is a Manufacturer of Ball Mill Solutions, Ball Mill Rubber Lining, Wear Protection Line, Resistant Rubber Liner, Embedded Rubber Liners, Conveyors Solutions, Impact Bed Assembly and Impact Pads, Belt Cleaners, Pulley Lagging, Ceramic Rubber Lagging Services, and Ceramic Rubber Lagging Sheet.

Ball Mill Lining Variations: Designing Wear Defense for Tough Industrial Settings

Overview

Sectors such as mining, metal refining, cement production, ceramics manufacturing, and handling of bulk materials operate in some of the most severe operational environments. Constant rubbing, heavy shock forces, corrosive liquids, and high operating heat put enormous strain on machinery. In these settings, unexpected shutdowns directly impact output goals, safety, and operational outlays.

In robust industrial settings, equipment dependability isn’t just an aim—it’s a daily necessity. Facility engineers and maintenance teams consistently focus on wear-defense systems that withstand real-world conditions while maintaining consistent performance over extended operational periods.

Globally, industries are shifting toward optimized lining arrangements that balance wear resistance, impact cushioning, and ease of maintenance. This need is evident across major mining areas, cement manufacturing hubs, steel mills, ceramic production zones, and bulk material handling depots.

Varieties of Ball Mill Liners hold a crucial place in this arena. Appropriately designed liners safeguard the mill shell, enhance grinding efficiency, and promote safer, more reliable facility operations across various industrial segments.

Industrial Obstacles Fueling the Need for Different Ball Mill Liners

Ball mills operate in environments where material stress is constant and unforgiving. Several ongoing issues spur the call for sophisticated lining solutions:

- Friction: Ores, clinker, slag, minerals, and uncooked ceramic items cause continuous abrasive wear. Over time, unprotected surfaces degrade, leading to reduced performance and structural harm.

- Impact Forces: Large grinding media and heavy input materials generate recurring high-shock loads. Liners must absorb blows without fracturing or transmitting strain to the mill casing.

- Corrosion: In mining and metal refining, dampness, chemical agents, and slurry conditions accelerate corrosion, particularly in wet grinding processes.

- Outages: Frequent lining replacements lead to prolonged stoppages. Lost production time often surpasses the expense of the parts themselves.

- Maintenance Outlays: Labor-intensive fitting, unsafe handling, and inconsistent lining lifespans directly impact upkeep budgets.

These difficulties are common across industrial settings worldwide, spanning iron ore pits and cement works to ceramic complexes and bulk depots.

What Constitutes Ball Mill Liner Types?

Ball Mill Liner Types denote engineered wear defense systems fitted inside ball mills to shield the shell and internal elements from attrition, shock, and chemical attack.

They represent more than a single product group; they are a spectrum of solutions tailored for distinct operational scenarios, including:

- Mill Rubber Liners

- Hard Ceramic Wear Tiles

- Rubber-Ceramic Hybrid Liners

Rubber Sheeting Systems for process machinery and mining gear

Each variation fulfills a specific function based on material specifics, mill rotation speed, grinding media size, and operational priorities. The goal isn’t simply the highest hardness, but also controlled wear patterns and a foreseeable service life.

Uses Throughout Industries

- Mining: Mill linings are extensively employed in plants processing iron ore, coal, limestone, copper, and other minerals. Liners cut down shell deterioration and enhance mill uptime during continuous processes.

- Cement: In cement grinding circuits, liners manage clinker abrasion while sustaining steady mill operation and regulated sound levels.

- Metal & Steel: Steel facilities utilize linings when grinding slag, treating sinter, and handling auxiliary materials where impact and friction are combined factors.

- Ceramics: Manufacturers processing materials like feldspar, quartz, and alumina depend on wear defense to preserve product purity and consistent form.

- Power Generation: Thermal and captive power stations use liners in coal pulverization and fly ash-handling systems.

- Bulk Material Transport: Conveyors, transfer points, and processing apparatus benefit from rubber and ceramic wear-defense systems that minimize spills and structural damage.

Material Science & Design Principles

Seasoned facility engineers often observe that lining effectiveness hinges more on the material’s behavior than on advertised hardness metrics.

- Rubber Characteristics: Industrial-grade rubber linings provide flexibility, impact damping, and sound reduction. Their elasticity permits them to flex under load and regain shape without breaking.

- Ceramic Rigidity: Ceramic wear plates offer superior abrasion resistance. Their hardness makes them suitable for areas with sliding friction but necessitates correct support and adhesion.

- Wear Resistance Concepts: Wear is influenced by particle size, impact speed, impact angle, and material toughness. Matching the lining material to the specific wear mechanisms is key.

- Impact Buffering: Rubber and composite linings lessen stress transfer to the mill casing, thus extending the gear’s service life.

This blend of rigidity and pliability defines proficient lining engineering.

Configuration & Tailoring Needs

No two mills function under absolutely identical settings. Effective lining setups necessitate:

- Suitability for the specific mill diameter, length, and spin rate

- Custom dimensions to align with lifting bar profiles and fastener patterns

- Design tailored to wet versus dry grinding circumstances

- Consideration of media size and incoming material attributes

Producers with extensive industry tenure recognize that customization isn’t an option—it’s fundamental for dependable outcomes.

Production Excellence & Process Oversight

Accurate manufacturing directly impacts lining dependability.

Crucial elements include:

- Managed raw material composition

- Precise shaping and curing procedures

- Checks on dimensional accuracy

- Uniformity between production batches

- Tracking of manufacturing documentation

Quality oversight ensures that linings behave as anticipated across numerous deployments, lowering operational unpredictability.

Fitting & Servicing Considerations

Fitting simplicity is a vital operational element.

Well-conceived linings offer:

- Lighter handling weight

- Streamlined fastener arrangements

- Quicker fitting durations

- Minimized risk during service periods

Optimized service intervals allow plants to schedule outages more effectively and curb production losses.

Safety & Operational Dependability

Worker protection is a primary, unwavering concern.

Appropriate lining systems contribute to:

- Reduced hazards from manual handling

- Lower sound and vibration levels

- Better mill stability

- Safeguarding of vital equipment elements

Dependable wear defense directly supports overall facility reliability and adherence to safety rules.

Cost Effectiveness Across the Equipment Lifespan

While the initial choice is important, true value lies in life-cycle performance.

Effective lining setups yield:

- Extended periods between services

- Fewer unplanned shutdowns

- Reduced labor for maintenance

- Consistent operating efficiency

Cost efficiency comes from predictable function, not short-term price reductions.

Export Readiness & Worldwide Acceptance

Global industrial purchasers look for:

- Adherence to international standards

- Thorough technical paperwork

- Consistent quality across consignments

- Confirmed industrial track records

Manufacturers ready for export understand the documentation, packaging, and performance verification needs of overseas markets.

Why Manufacturer Experience Counts

In industrial wear defense, expertise cannot be substituted merely by specifications.

Experienced manufacturers deliver:

- Engineering support driven by real-world application

- Reliable material supply chains

- Long-term product consistency

- Pragmatic solutions based on field observation

This depth of knowledge lessens risk for facility supervisors and project advisors.

About Mouldtech Industries

Mouldtech Industries is an established industrial producer specializing in ball mill rubber linings, complex ceramic wear defense systems, rubber lining setups, rubber mill components, and conveyor solutions.

Serving industrial sectors across India—including mining, cement, metal, ceramic, and bulk material handling—Mouldtech Industries supports operations throughout all Indian territories—from Maharashtra, Gujarat, Rajasthan, Odisha, Chhattisgarh, Jharkhand, Karnataka, Tamil Nadu, Andhra Pradesh, Telangana, West Bengal, Punjab, Haryana, Uttar Pradesh, Madhya Pradesh, Bihar, Assam, and Kerala to industrial centers like Ahmedabad, Vadodara, Surat, Mumbai, Pune, Nagpur, Jaipur, Udaipur, Bhilai, Rourkela, Jamshedpur, Durgapur, Chennai, Coimbatore, Salem, Bengaluru, Hyderabad, Visakhapatnam, Vijayawada, Kolkata, Raipur, Ranchi, Bokaro, Angul, Talcher, and numerous others.

With an awareness of global industrial demands, the firm supports both domestic and overseas initiatives https://www.mouldtechindustries.in/

Summary

Ball Mill Liner Types play a crucial role in safeguarding machinery, maintaining operational stability, and enhancing long-term facility efficiency. When designed and selected appropriately, they address genuine industrial challenges related to wear, impact, safety, and maintenance planning.

For industries operating under constant load and stringent conditions, lining systems are not mere expendables—they are strategic elements of facility dependability.

A thoughtful review of operating settings and support from seasoned manufacturers ensures sustained performance throughout the equipment’s service life.

Key Facts to Note

- Wear defense is vital in environments rife with friction and impact

- Correct lining selection boosts operational trustworthiness

- Rubber and ceramic options cater to diverse wear patterns

- Bespoke design ensures steady functioning

- Proven production background supports lasting facility productivity

Trending FAQs

1. What is the typical lifespan of ball mill liners?

Liner life depends on material, operating conditions, feed characteristics, and maintenance practices.

2. Are rubber liners suitable for heavy impact applications?

Yes, rubber liners absorb impact effectively, especially in high-impact grinding environments.

3. How often do ball mill liners require maintenance?

Inspection intervals vary, but experienced plants align maintenance with planned shutdown cycles.

4. Rubber vs ceramic wear solutions—how do they differ?

Rubber offers impact absorption, while ceramic provides high abrasion resistance. Selection depends on wear type.

5. Are these linear systems used globally?

Yes, mining, cement, and metal industries worldwide use rubber and ceramic liner systems.

Connect with Mouldtech Industries for high-performance Types of Ball Mill Liners. Our engineering team delivers reliable wear protection solutions, ensuring safer, efficient, and long-lasting operations for mining, cement, and steel plants.

#BallMillRubberLiner #CeramicWearProtection #RubberLining #MiningSolutions #BulkMaterialHandling #ConveyorSolutions #MouldtechIndustries #WearProtection #IndustrialManufacturing