Ceramic Lagging Sheet Manufacturer, Supplier, And Exporter in India: Mouldtech Industries

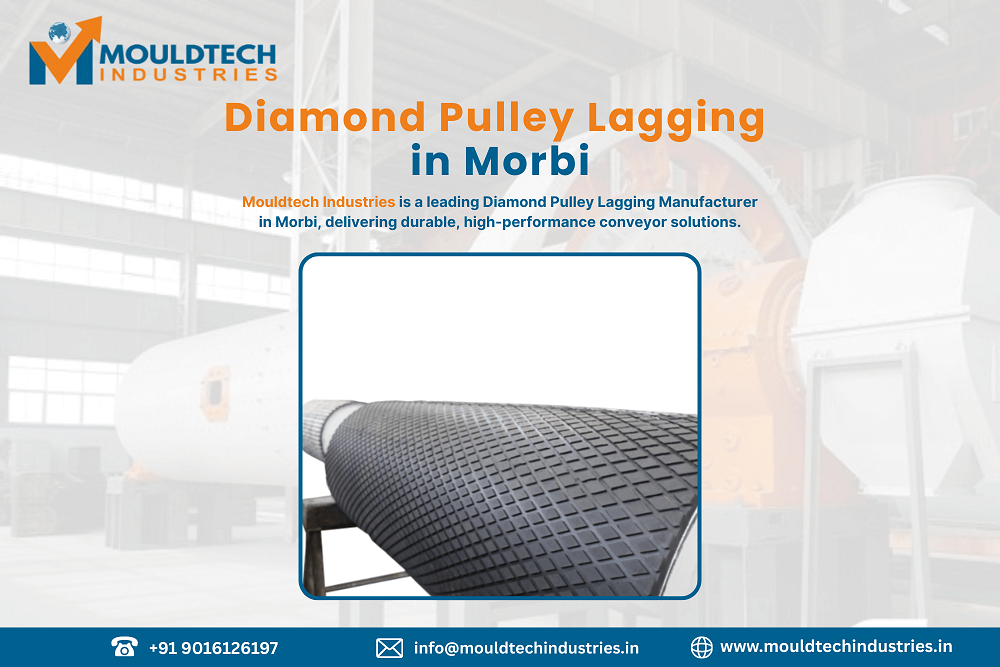

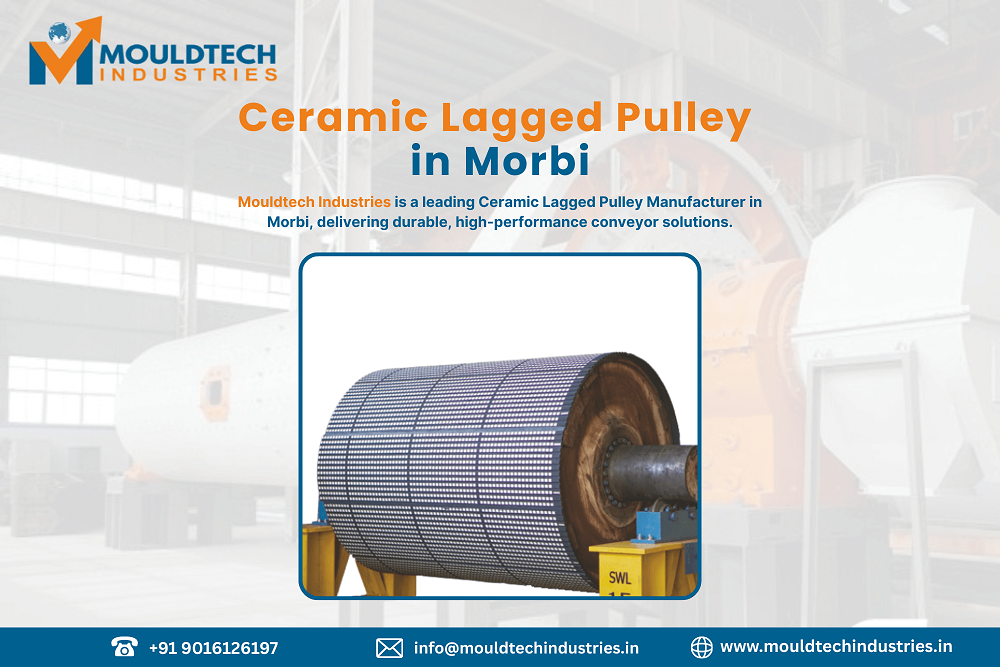

Mouldtech Industries is a Manufacturer of Ceramic Lagging Sheet in Morbi.

Our Manufacturing Unit is in Vadodara, Gujarat, India.

Mouldtech Industries is a Manufacturer of Bridge Rubber Pad, Ball Mill Rubber Lining, Bridge Rubber Pad, Resistant Rubber Liner, Embedded Rubber Liners, Conveyors Solutions, Ceramic Lagging Sheet, Belt Cleaners, Bridge Rubber Pad, Ceramic Rubber Lagging Services, and Ceramic Rubber Lagging Sheet.

Ceramic Lagging Sheet: Essential Wear Protection for Heavy-Duty Industrial Operations

Introduction

In heavy-duty industrial environments, equipment reliability and wear protection are central to operational efficiency. Mining companies, metal and steel plants, cement manufacturers, ceramic production units, and bulk material handling operations face relentless wear challenges. Abrasive ores, high-impact materials, and corrosive substances can significantly reduce the lifespan of critical equipment like ball mills, conveyors, and chutes.

Globally, industrial trends indicate an increasing focus on materials and solutions that enhance durability, reduce downtime, and optimize maintenance cycles. Amidst these demands, the Ceramic Lagging Sheet has emerged as a vital industrial solution, offering targeted protection against abrasion and impact while maintaining operational efficiency.

Industrial Challenges That Drive Demand for Ceramic Lagging Sheet

Industries such as mining, cement, metal, and ceramics regularly encounter several operational challenges:

- Abrasion: Continuous movement of hard, granular materials erodes metal surfaces, causing premature wear.

- Impact Loads: Heavy material drops in ball mills or hoppers induce high-stress impacts, leading to equipment fatigue.

- Corrosion: Exposure to moisture, chemicals, and metallic oxides accelerates surface degradation.

- Downtime: Unplanned maintenance due to wear can halt production, affecting project timelines and revenues.

- Maintenance Cost: Replacing or repairing worn equipment components drives operational expenses.

In mining hubs across Odisha, Jharkhand, and Rajasthan, ceramic clusters in West Bengal, and metal & steel plants in Chhattisgarh and Maharashtra, these challenges are commonplace. Experienced plant engineers often observe that even minor improvements in wear protection can yield measurable efficiency gains.

What Is Ceramic Lagging Sheet?

A Ceramic Lagging Sheet is an engineered composite that integrates high-grade rubber with embedded ceramic tiles to provide enhanced wear resistance. Unlike conventional metal liners, ceramic lagging sheets combine the shock-absorbing properties of rubber with the hardness and abrasion resistance of ceramics.

In industrial terms, these sheets are designed to line the internal surfaces of ball mills, conveyors, and hoppers, where high-impact and abrasive materials come into contact. The ceramic segments absorb surface wear, while the rubber substrate cushions impact loads, minimizing stress on underlying equipment structures.

Applications Across Industries

The Ceramic Lagging Sheet finds practical applications across multiple heavy-duty industrial sectors:

- Mining: Lining ball mills, grinding mills, and ore chutes to prevent metal erosion and extend equipment life.

- Cement Plants: Protecting clinker conveyors, bucket elevators, and rotary kilns from abrasive materials.

- Metal & Steel Plants: Shielding conveyor systems, slag chutes, and hoppers handling iron ore, pellets, and metallic scrap.

- Ceramic Manufacturers: Protecting kilns, mixers, and material transport lines from abrasive clay, tiles, and glaze residues.

- Power Plants: Mitigating wear in coal handling systems and ash conveyors.

- Bulk Material Handling: Safeguarding hoppers, feeders, and belt conveyors in ports, logistics yards, and industrial warehouses.

In each application, the combination of rubber flexibility and ceramic hardness ensures optimal wear resistance and impact absorption.

Material Science & Engineering Considerations

From an engineering perspective, the effectiveness of ceramic lagging sheets depends on material properties and integration:

- Rubber Properties: High-quality natural or synthetic rubber provides elasticity, damping vibrations, and distributing impact forces over a wider area.

- Ceramic Hardness: Ceramic inserts exhibit exceptional hardness, resisting abrasive wear even under high-speed material flow.

- Wear Resistance Principles: The combination of hardness and elasticity reduces localized wear, extending service life.

- Impact Absorption: Rubber cushions impacts, preventing structural damage to machinery and reducing noise and vibration.

Manufacturers with long-term industry exposure understand that precise selection of ceramic grades and rubber compounds is critical for ensuring consistent performance under varying operational loads.

Design & Customization Requirements

Every plant operation is unique, requiring tailored solutions:

- Equipment Compatibility: Sheets must match the curvature, pitch, and dimension of mills, hoppers, or conveyor drums.

- Custom Sizing: Modular or full-coverage sheets can be fabricated based on material flow, impact zones, and installation constraints.

- Application-Specific Design: Ceramic tile placement, rubber thickness, and sheet backing must be engineered to balance abrasion resistance with impact absorption.

Design engineers often collaborate with manufacturers to ensure the solution aligns with operational parameters, maximizing longevity and efficiency.

Manufacturing Quality & Process Control

Reliable performance starts with meticulous manufacturing:

- Precision Manufacturing: Rubber and ceramic composites are molded with strict dimensional tolerances to ensure proper fit.

- Quality Checks: Visual inspection, hardness testing, and adhesion checks prevent premature failure.

- Batch Consistency: Consistent production ensures predictable wear resistance, a critical factor for planning maintenance cycles in large-scale plants.

Precision in manufacturing reduces installation challenges and guarantees consistent operational performance in heavy-duty environments.

Installation & Maintenance Considerations

Experienced plant engineers often emphasize that installation is as critical as material quality:

- Ease of Installation: Modular sheets reduce downtime during replacement and maintenance.

- Reduced Downtime: Pre-fabricated sheets with mounting provisions allow rapid installation without extensive plant shutdown.

- Maintenance Cycles: Periodic inspections identify wear patterns early, allowing selective replacement rather than full-line shutdowns.

Proper installation ensures the protective system performs effectively over its intended service life.

Safety & Operational Reliability

Worker safety and plant reliability are paramount:

- Worker Safety: Rubber-backed ceramic sheets reduce the risk of sharp metal exposure and minimize vibration transmission.

- Equipment Protection: Cushioning impact extends the life of drum shells, mill liners, and conveyor structures.

- Plant Reliability: Reduced unscheduled downtime ensures consistent production flow, crucial in mining and bulk material industries.

Cost Efficiency Over Equipment Life Cycle

While initial investment may seem higher, long-term cost efficiency is significant:

- Long-Term Savings: Reduced wear minimizes the frequency of replacement components.

- Reduced Shutdowns: Operational continuity lowers lost production costs.

- Maintenance Optimization: Predictable wear patterns allow for scheduled maintenance, avoiding emergency repairs and unscheduled downtime.

Experienced plant engineers often observe that lifecycle cost savings outweigh the upfront expense of high-quality ceramic lagging sheets.

Export Readiness & Global Acceptance

For industrial manufacturers in India targeting global markets, compliance and documentation are crucial:

- Industrial Export Expectations: Sheets must meet international quality and performance standards.

- Documentation & Standards Awareness: ISO certifications, material specifications, and batch traceability are essential for global buyers.

- Global Buyer Requirements: Mining and bulk material handling operations in Southeast Asia, Africa, and the Middle East often demand proven performance and documentation.

Why Experienced Manufacturers Matter

Manufacturers with proven expertise provide reliability and trust:

- Engineering Expertise: Knowledge of material properties and industrial wear patterns ensures practical, durable solutions.

- Industry Experience: Long-term exposure helps anticipate challenges in mining, metal processing, cement, and ceramic industries.

- Reliable Supply: Consistent production and on-time delivery are critical for large-scale industrial operations.

About Mouldtech Industries

Mouldtech Industries is a trusted manufacturer of [Ceramic Lagging Sheets], serving industrial clients across India, including cities in Odisha, Jharkhand, Chhattisgarh, Maharashtra, West Bengal, Tamil Nadu, Karnataka, and Gujarat. The company also supplies solutions to international industrial markets, adhering to stringent quality standards and ensuring long-term reliability.

For detailed product specifications and engineering consultation, visit: https://www.mouldtechindustries.in/

Conclusion

In mining and metal processing operations, as well as cement, ceramic, and bulk material handling industries, Ceramic Lagging Sheet plays a critical role in extending equipment life, reducing downtime, and optimizing maintenance costs. Engineered with precise material science and industrial insight, it provides a durable, safe, and reliable wear protection solution.

Industrial engineers and plant managers should consider ceramic lagging sheets as a strategic investment in operational efficiency and equipment longevity.

Key Takeaways

- Effective wear protection against abrasion and impact

- Enhanced operational reliability and reduced downtime

- Suitable across mining, cement, metal, ceramic, and bulk handling industries

- Long-term performance with predictable maintenance cycles

- Globally accepted for industrial export and compliance

Trending FAQs

Q1: What is the typical lifespan of a Ceramic Lagging Sheet?

A: In heavy-duty industrial environments, they typically last 3–5 years, depending on material type, impact load, and maintenance practices.

Q2: Which industries benefit most from Ceramic Lagging Sheets?

A: Mining, cement, metal and steel, ceramic manufacturing, power plants, and bulk material handling operations.

Q3: How often should maintenance or inspection be carried out?

A: Experienced plant engineers recommend quarterly inspections, with selective replacement as wear pattern

Contact Mouldtech Industries for premium Ceramic Lagging Sheets. Our experts provide industrial solutions across mining, cement, metal, and bulk handling sectors.

#CeramicLaggingSheet #BallMillRubberLiner #CeramicWearProtection #RubberLiningSystems #ConveyorSolutions #MiningSolutions #BulkMaterialHandling #IndustrialWearProtection #MouldtechIndustries #EquipmentReliability