Diamond Groove Sheet Manufacturer, Supplier, And Exporter in India: Mouldtech Industries

Mouldtech Industries is a Manufacturer of Diamond Groove Sheet in Morbi.

Our Manufacturing Unit is in Vadodara, Gujarat, India.

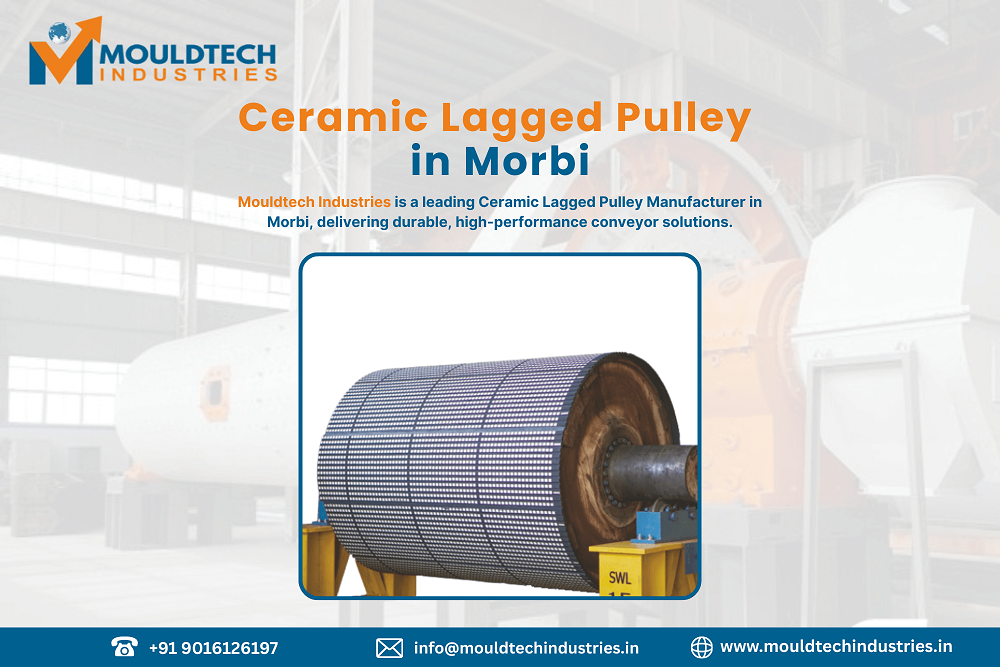

Mouldtech Industries is a Manufacturer of Bridge Rubber Pad, Ball Mill Rubber Lining, Bridge Rubber Pad, Resistant Rubber Liner, Embedded Rubber Liners, Conveyors Solutions, Ceramic Lagging Sheet, Belt Cleaners, Bridge Rubber Pad, Ceramic Rubber Lagging Services, and Ceramic Rubber Lagging Sheet.

Diamond Groove Sheet: A Critical Solution for Industrial Wear Protection

Introduction

In heavy-duty industrial environments, operations in mining, metal, cement, ceramic, and bulk material handling plants face constant challenges. Abrasion from abrasive ores, impact from heavy loads, and corrosion from chemical exposure are daily realities. Equipment reliability is no longer optional—it directly affects productivity, operational costs, and plant safety.

Wear protection solutions are, therefore, a cornerstone of industrial efficiency. Downtime caused by worn-out liners, damaged conveyors, or inefficient impact-absorbing systems can result in significant financial losses and production delays. Global industrial trends show a rising demand for durable wear protection systems in mining hubs, steel-producing regions, and ceramic clusters, particularly across Pan India—including Maharashtra, Gujarat, Rajasthan, Tamil Nadu, Karnataka, Andhra Pradesh, Odisha, and West Bengal.

Among these solutions, the Diamond Groove Sheet has emerged as a reliable component for safeguarding equipment. Designed for demanding environments, it addresses wear challenges without compromising operational reliability.

Industrial Challenges That Drive Demand for Diamond Groove Sheet

Experienced plant engineers often observe that in mining and metal processing operations, equipment faces several recurring challenges:

- Abrasion: Constant friction from ores, minerals, and aggregates leads to gradual material loss on chutes, hoppers, and conveyors.

- Impact Loads: Heavy lumps or dropped material repeatedly strike surfaces, causing deformation, cracking, and eventual failure.

- Corrosion: In cement, chemical processing, and specific mineral applications, exposure to moisture and chemicals accelerates material degradation.

- Downtime: Equipment downtime due to liner wear or conveyor damage directly reduces plant throughput.

- Maintenance Costs: Frequent replacements, labour-intensive interventions, and unscheduled shutdowns increase operational expenditure.

Globally, industrial hubs in South America, Southeast Asia, and Australia face similar issues, driving the adoption of engineered wear protection solutions such as the Diamond Groove Sheet.

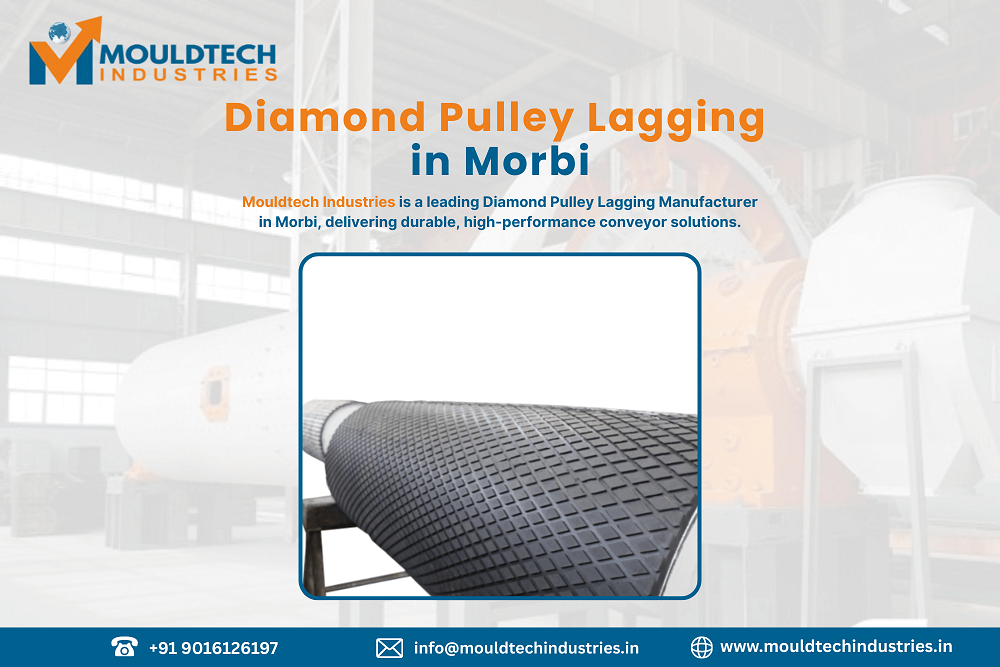

What Is Diamond Groove Sheet?

In industrial engineering terms, the Diamond Groove Sheet is a wear protection panel engineered for impact resistance, abrasion mitigation, and operational durability. It typically consists of high-quality rubber or ceramic composites shaped in a grooved, diamond-patterned surface. This configuration distributes loads evenly, reduces frictional wear, and enhances material flow.

Unlike standard liners, these sheets are engineered to integrate seamlessly with equipment while offering predictable performance under high-stress conditions. Manufacturers with long-term industry exposure understand that such products must balance toughness with elasticity, enabling both energy absorption and material resilience.

Applications Across Industries

Diamond Groove Sheets find practical applications across several heavy industries:

- Mining: Protects chutes, hoppers, and mills from abrasive ores and heavy material impacts. Commonly installed in coal, iron ore, bauxite, and limestone handling systems.

- Cement Plants: Shields kiln feed chutes, clinker transport systems, and grinding mill linings from abrasive cement raw materials.

- Metal & Steel Plants: Reduces wear on slag handling conveyors, rolling mills, and scrap material chutes.

- Ceramic Manufacturing: Safeguards kilns, mixers, and handling equipment from abrasive clay and ceramic powders.

- Power Plants: Protects ash handling systems, coal feeders, and bulk material conveyors from abrasive and corrosive loads.

- Bulk Material Handling: Supports aggregate, sand, fertilizer, and grain handling infrastructure by reducing wear and extending service life.

In these contexts, the Diamond Groove Sheet contributes to predictable maintenance cycles and safer operations.

Material Science & Engineering Considerations

The performance of a Diamond Groove Sheet relies heavily on material science principles:

- Rubber Properties: High-quality rubber offers elasticity, shock absorption, and chemical resistance. It allows the liner to deform under impact, preventing structural damage to equipment.

- Ceramic Hardness: For extreme abrasion resistance, ceramic composites maintain structural integrity against sharp or hard materials. Engineers select ceramic grades based on Mohs hardness, thermal resistance, and chemical stability.

- Wear Resistance Principles: Groove patterns enhance material flow while distributing impact forces, reducing localized wear.

- Impact Absorption: Energy from falling or moving materials is absorbed across the sheet surface, minimizing stress on underlying equipment.

Such considerations are critical when designing liners for industrial operations where both abrasion and impact loads occur simultaneously.

Design & Customization Requirements

Manufacturers with long-term industry exposure understand that one-size-fits-all solutions rarely meet plant-level requirements. Design and customization include:

- Equipment Compatibility: Diamond Groove Sheets are tailored for mills, chutes, hoppers, and conveyor surfaces. Compatibility ensures secure attachment and full coverage.

- Custom Sizing: Sheets are produced in dimensions specific to plant equipment, reducing on-site cutting and installation time.

- Application-Specific Design: Engineers specify groove depth, pattern orientation, and composite material based on whether abrasion, impact, or chemical exposure predominates.

Proper customization ensures operational efficiency and maximizes liner service life.

Manufacturing Quality & Process Control

In heavy-duty industrial environments, precision manufacturing is essential:

- Precision Manufacturing: Sheets are moulded or pressed under controlled conditions, ensuring consistent thickness, pattern alignment, and density.

- Quality Checks: Dimensional accuracy, hardness, tensile strength, and chemical resistance are tested batch-wise.

- Batch Consistency: Uniformity ensures predictable performance across multiple installations, crucial for large-scale plants or multi-site operations.

Manufacturers that follow these protocols maintain reliability and build trust with plant engineers and procurement teams.

Installation & Maintenance Considerations

Installation and maintenance are key to operational reliability:

- Ease of Installation: Diamond Groove Sheets are designed for bolting, adhesive bonding, or interlocking installation, minimizing labour requirements.

- Reduced Downtime: Quick installation reduces production interruptions, particularly in critical processing lines.

- Maintenance Cycles: Predictable wear rates allow engineers to schedule replacements during planned maintenance, avoiding emergency downtime.

Experienced plant engineers often observe that planning installation and maintenance alongside liner selection significantly extends equipment life.

Safety & Operational Reliability

Worker safety and plant reliability are enhanced through:

- Worker Safety: Shock-absorbing liners reduce equipment vibration and prevent accidental material ricochet.

- Equipment Protection: Grooved sheets minimize surface damage, extending the operational life of mills, chutes, and conveyors.

- Plant Reliability: Reducing unplanned downtime and equipment failure maintains steady throughput and operational continuity.

In mining and metal processing operations, these factors directly contribute to plant performance and worker well-being.

Cost Efficiency Over Equipment Life Cycle

While upfront costs may be significant, the long-term value is evident:

- Long-Term Savings: Reduced wear and fewer replacements lead to measurable operational savings.

- Reduced Shutdowns: Scheduled maintenance prevents unscheduled downtime, avoiding productivity losses.

- Maintenance Optimization: Predictable wear allows maintenance teams to plan interventions efficiently, reducing labour and resource usage.

Industries adopting such solutions achieve tangible improvements in operational budgets over the equipment life cycle.

Export Readiness & Global Acceptance

Industrial export markets demand compliance with stringent standards:

- Global buyers require quality documentation, material certification, and durability testing for industrial exports.

- Standards Awareness: International standards for wear protection and material safety guide manufacturing processes.

- Global Buyer Requirements: Mining hubs, steel plants, and ceramic manufacturers worldwide expect predictable performance and verified material properties.

Domestic and international industrial clients prefer manufacturers that meet these expectations.

Why Experienced Manufacturers Matter

In heavy-duty industrial environments, selecting a manufacturer with proven expertise is critical:

- Engineering Expertise: Understanding operational conditions allows precise material selection and design.

- Industry Experience: Years of exposure across mining, cement, metal, and ceramic plants ensure practical solutions.

- Reliable Supply: Consistent production and on-time delivery maintain plant schedules and project commitments.

Mouldtech Industries exemplifies such expertise, delivering reliable wear protection solutions across India and international markets.

About Mouldtech Industries

Mouldtech Industries has decades of experience serving industrial sectors across Pan India, including Maharashtra, Gujarat, Rajasthan, Tamil Nadu, Karnataka, Andhra Pradesh, Odisha, and West Bengal. Their offerings encompass Ball Mill Rubber Liners, Ceramic Wear Protection Solutions, Rubber Lining Systems, Diamond Groove Sheets, and Conveyor Solutions.

With an emphasis on quality, precision manufacturing, and operational reliability, Mouldtech Industries supports plant engineers, maintenance teams, and OEMs with solutions designed for the realities of industrial operations.

Conclusion

In mining, metal, cement, ceramic, and bulk material handling operations, equipment reliability and wear protection are essential. The Diamond Groove Sheet offers a robust solution to abrasion, impact, and corrosion challenges, helping plants maintain productivity, reduce downtime, and optimize maintenance cycles.

For plant engineers and procurement managers seeking durable, engineered wear protection, integrating Diamond Groove Sheets into operational strategies enhances both safety and efficiency.

Key Takeaways

- Wear protection mitigates abrasion, impact, and corrosion.

- Enhances operational reliability and plant safety.

- Suitable across mining, cement, metal, ceramic, and bulk material handling industries.

- Supports long-term performance and predictable maintenance cycles.

- Recognized in global industrial markets for durability and consistency.

Trending FAQs

Q1: What is the typical lifespan of a Diamond Groove Sheet?

A1: Lifespan depends on material grade, impact and abrasion load, but in heavy-duty operations, sheets can last several years with proper maintenance.

Q2: Can Diamond Groove Sheets be used in cement and steel plants?

A2: Yes. They are effective in chutes, hoppers, conveyors, and mills across cement and steel operations.

Q3: How frequently should maintenance or inspection be performed?

A3: Experienced plant engineers recommend periodic inspection aligned with scheduled maintenance cycles to replace or reposition sheets before excessive wear occurs.

Q4: When should one choose rubber over ceramic wear solutions?

A4: Rubber is preferable for impact absorption and chemical resistance, while ceramics are ideal for extreme abrasion and handling high-hardness materials.

Q5: Are Diamond Groove Sheets used internationally?

A5: Yes. Mining hubs, steel plants, and bulk handling industries across South America, Southeast Asia, and Australia widely adopt them.

Contact Mouldtech Industries for expert guidance and supply of Diamond Groove Sheet. Our team supports Pan India industrial operations with reliable wear protection solutions.

#DiamondGrooveSheet #BallMillRubberLiner #CeramicWearProtection #RubberLiningSystems #BallMillRubberProducts #ConveyorSolutions #IndustrialWearProtection #MouldtechIndustries