Ball Mill Rubber Lining Manufacturer, Supplier, And Exporter in India: Mouldtech Industries

Mouldtech Industries is a Manufacturer of Ball Mill Rubber Lining in Morbi.

Our Manufacturing Unit is in Vadodara, Gujarat, India.

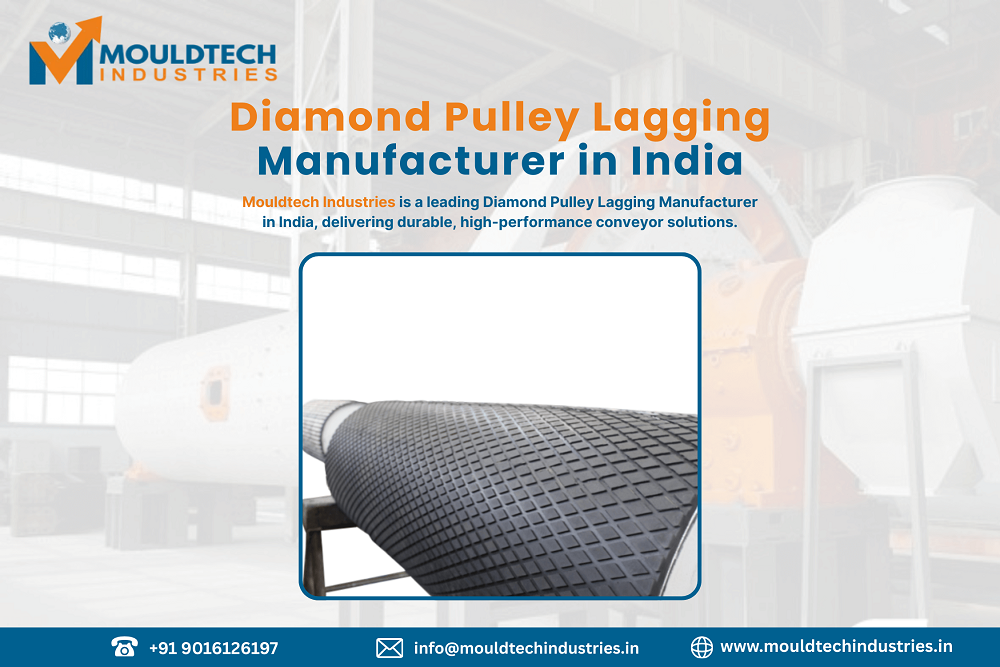

Mouldtech Industries is a Manufacturer of Bridge Rubber Pad, Ball Mill Rubber Lining, Bridge Rubber Pad, Resistant Rubber Liner, Embedded Rubber Liners, Conveyors Solutions, Ceramic Lagging Sheet, Belt Cleaners, Bridge Rubber Pad, Ceramic Rubber Lagging Services, and Ceramic Rubber Lagging Sheet.

Ball Mill Rubber Linings: Engineered Defense Against Wear in Tough Industrial Settings

Introduction

Sectors such as mining, metal refining, cement production, ceramics, and bulk material movement face some of the most severe mechanical stresses. Consistent material flow, abrasive ores, high humidity, temperature swings, and heavy impacts severely tax machinery. Among rotating assets, ball mills are significant wear points in any facility.

Unscheduled halts in these fields are seldom just a maintenance concern; they hit production targets, energy use effectiveness, worker safety, and overall spending. As operations expand across India—from key mining zones to ceramic centers and steel hubs—the need for dependable wear-defense systems continues to grow.

In demanding industrial settings, wear defense is a fundamental engineering prerequisite, not an optional extra. Ball Mill Rubber Lining has become a vital solution, helping boost equipment reliability, reduce maintenance needs, and extend the operational life of grinding equipment across India’s industrial areas.

Industrial Hurdles Driving Demand for Ball Mill Rubber Lining

Seasoned plant personnel often note that most ball mill failures occur gradually rather than abruptly. Key issues include:

- Abrasion: Grinding media, raw mineral inputs, clinker, slag, and ceramic substances cause constant surface erosion. Steel plates suffer faster material loss in areas with high abrasion.

- Impact Forces: Ball mills endure repeated blows from grinding media during operation. These dynamic forces are transmitted straight to the liner setup.

- Corrosion: In mining and metal processing, moisture, chemical additions, and slurry conditions can cause liners to deteriorate due to corrosion.

- Stoppages & Maintenance Schedules: Frequent liner replacement leads to more extended downtime, increased reliance on cranes, and greater worker exposure.

- Maintenance Cost Pressures: Beyond the cost of the liners themselves, facilities incur secondary expenses—lost output, poorer energy efficiency, and safety hazards.

These difficulties are widespread across global industrial scenes, spanning Indian iron ore regions, cement factories, ceramic manufacturing hubs, and bulk terminals.

What Exactly Is Ball Mill Rubber Lining?

Ball Mill Rubber Lining is a wear-resistant lining installed inside the ball mill shell. Unlike metal plates, rubber linings use specialized elastomer blends to absorb impact energy while resisting abrasion.

Its primary purpose is to manage wear predictably, not eliminate it. Rubber linings reduce direct metal-on-metal contact, absorb shocks, and protect the mill shell from structural damage.

In operational terms, rubber liners serve as a sacrificial, energy-dampening interface between the grinding media and the mill structure.

Uses Across Different Industries

- Mining Sector: Utilized in primary and secondary grinding mills processing iron ore, coal, bauxite, limestone, and base metals in India’s mining territories.

- Cement Plants: Applied in raw and finish grinding mills, where clinker wear and impact forces are constant operational problems.

- Metal & Steel Operations: Deployed in slag grinding, mineral preparation units, and secondary milling tasks.

- Ceramic Manufacturing: Used in mills grinding feldspar, quartz, and ceramic bodies where maintaining purity and consistent wear characteristics is essential.

- Power Generation Facilities: Applied in coal grinding and ash handling systems facing persistent wear and vibration issues.

- Bulk Material Transport: Supporting roles alongside conveyor belts, belt cleaners, and ceramic wear defense assemblies.

Material Science & Engineering Considerations

Producers with extensive industry tenure know that rubber performance hinges on its composition—not just its softness.

Core engineering concepts involve:

- Elasticity: Balancing flexibility with structural robustness.

- Wear Resistance: Selecting the compound based on the hardness of the material being processed.

- Impact Damping: Dissipating energy through elastomer flexing.

- Bonding Strength: Ensuring secure attachment and backing design.

Ceramic wear tiles are frequently incorporated into rubber systems in high-wear spots, merging the hardness of ceramic with the impact absorption of rubber.

This combined engineering approach boosts service life without negatively affecting mill dynamics.

Design & Customization Demands

No two ball mills operate under identical circumstances. Effective rubber lining necessitates:

- Compatibility with mill dimensions and length.

- Tuning the geometry of the lifter bars.

- Accounting for media size and rotation speed.

- Understanding the input material characteristics.

- Specific shell attachment configurations.

Tailored sizing and application-specific design guarantee appropriate load distribution and liner stability throughout operational cycles.

Manufacturing Excellence & Process Oversight

The performance of industrial rubber lining is closely tied to manufacturing rigor.

Key factors for quality include:

- Strict control over compounding and vulcanization times.

- Accuracy in mold dimensions.

- Consistency of material from one production batch to the next.

- Testing of physical properties.

- Visual and measurable inspections.

Precise manufacturing ensures liners perform as intended—not just in lab settings, but in actual plant use.

Mounting & Servicing Notes

From an operational viewpoint, ease of installation is crucial.

Rubber linings are generally lighter than their metal counterparts, enabling:

- Quicker setup times.

- Reduced reliance on lifting gear.

- Less physical strain on personnel.

- Better control over alignment.

Service intervals become more predictable, helping teams schedule stoppages with minimal disruption to output plans.

Safety & Operational Dependability

Safety is an advantage of rubber lining setups that is sometimes overlooked.

Key benefits for operational safety comprise:

- Lowered noise levels.

- Reduced transmission of vibration.

- Handling liners during fitting is associated with a lower risk.

- Better shielding for the mill shell.

Equipment dependability improves when wear progression is managed proactively rather than reactively.

Cost Effectiveness Across the Equipment’s Service Life

While initial price comparisons are everyday, seasoned users assess performance over the equipment’s entire service life.

Long-term savings derive from:

- Fewer unscheduled outages.

- Extended shell longevity.

- Less frequent maintenance involvement.

- Improved energy usage due to stable mill operation.

The true worth lies in predictable functionality—not merely short-term expense figures.

Export Readiness & International Acceptance

Industrial purchasers anticipate uniformity, thorough documentation, and transparent procedures.

Manufacturers ready for export recognize:

- Global material benchmarks.

- Requirements for tracking material origins.

- Needs for technical paperwork.

- Expectations for application support.

Ball mill rubber lining solutions developed for Indian industries are increasingly gaining traction in global markets where dependability and engineering credibility are valued.

Why Experienced Manufacturers Are Important

Wear defense is an engineered system, not just an off-the-shelf item.

Manufacturers with hands-on industry background provide:

- Deep understanding of applications.

- Capacity to solve problems.

- Consistency in process.

- Dependable supply over the long haul.

This expertise directly translates to better plant uptime and greater operational assurance.

About Mouldtech Industries

Mouldtech Industries is an experienced industrial producer specializing in ball mill rubber linings, ceramic wear protection systems, rubber lining assemblies, rubber products for ball mills, conveyor systems, marine impact buffers, and wear components for bulk material handling.

Serving diverse sectors across India—including primary mining, cement, ceramic, and metal processing areas. Mouldtech Industries assists plant engineers, purchasing units, and project advisors with application-focused wear defense solutions.

Further details can be found at https://www.mouldtechindustries.in/

Conclusion

Ball Mill Rubber Lining serves a crucial function in contemporary industrial activities where controlling wear, ensuring safety, and maintaining reliability directly influence output.

In mining, cement, metal, ceramic, and bulk material handling environments, thoughtfully designed rubber lining setups help plants run more consistently, ease maintenance burdens, and safeguard essential machinery.

Selecting the appropriate solution—and the right manufacturing collaborator—remains a strategic operational choice rather than a simple procurement task.

Key Takeaways

- Dependable wear defense boosts equipment reliability.

- Rubber liners absorb impacts and lessen vibration.

- Suitable for mining, cement, ceramic, and metal sectors.

- Improves safety and aids in maintenance planning.

- Supports sustained operational performance.

- Relevant to both the Indian and global industrial arenas.

Trending FAQs

Q1. What is the typical service life of a ball mill rubber liner?

Service life varies based on material abrasiveness, mill speed, and running conditions. Properly designed liners offer predictable wear cycles.

Q2. Are rubber linings effective for heavy-duty mining tasks?

Yes. In mining and metal refining operations, rubber linings are widely used to manage impact and abrasion.

Q3. How frequently do rubber liners require attention?

Inspection schedules are typically coordinated with planned downtime, minimizing the need for emergency servicing.

Q4. Rubber versus ceramic wear solutions—what sets them apart?

Rubber cushions impact, while ceramic offers superior resistance to wear. Hybrid systems merge both advantages.

Q5. Are these solutions used internationally?

Yes. Ball mill rubber lining systems are accepted across global mining, cement, and industrial processing markets.

Q6. Is fitting them complicated?

Compared to metal plates, rubber liners are lighter and generally simpler to install with reduced safety concerns.

For Ball Mill Rubber Lining expertise, contact Mouldtech Industries today. Our technical team provides reliable engineering support for industrial wear protection needs across India.

#BallMillRubberLining #BallMillRubberLiner #RubberLiningSystems #BallMillRubberProducts #CeramicWearProtection #WearProtectionSolutions #MiningIndustry #CementPlants #MetalProcessing #BulkMaterialHandling #IndustrialWearSolutions #MouldtechIndustries