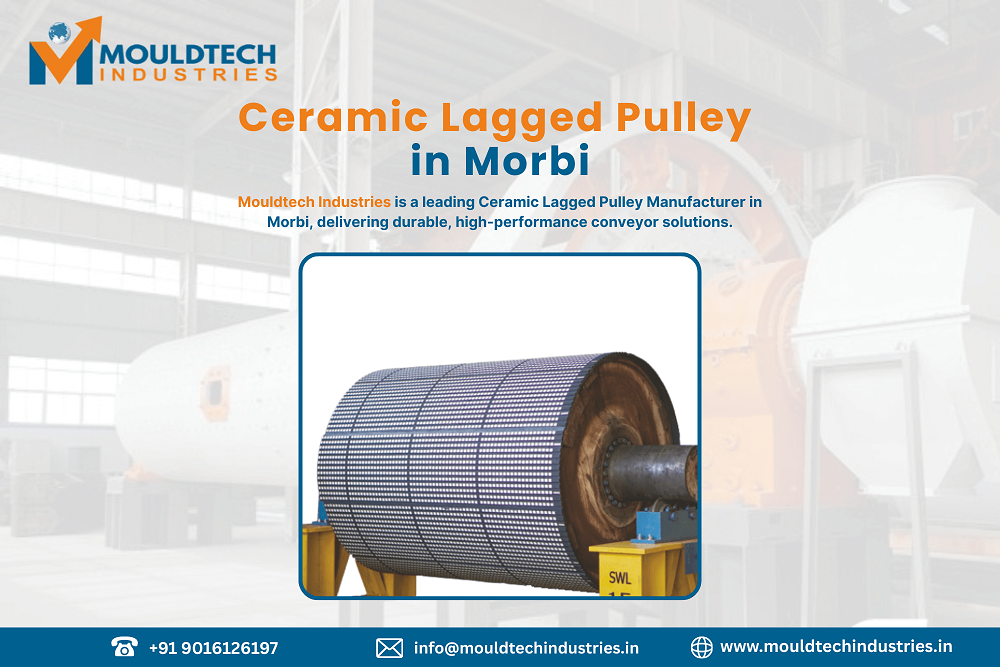

Ceramic Lagged Pulley Manufacturer, Supplier, And Exporter in India: Mouldtech Industries

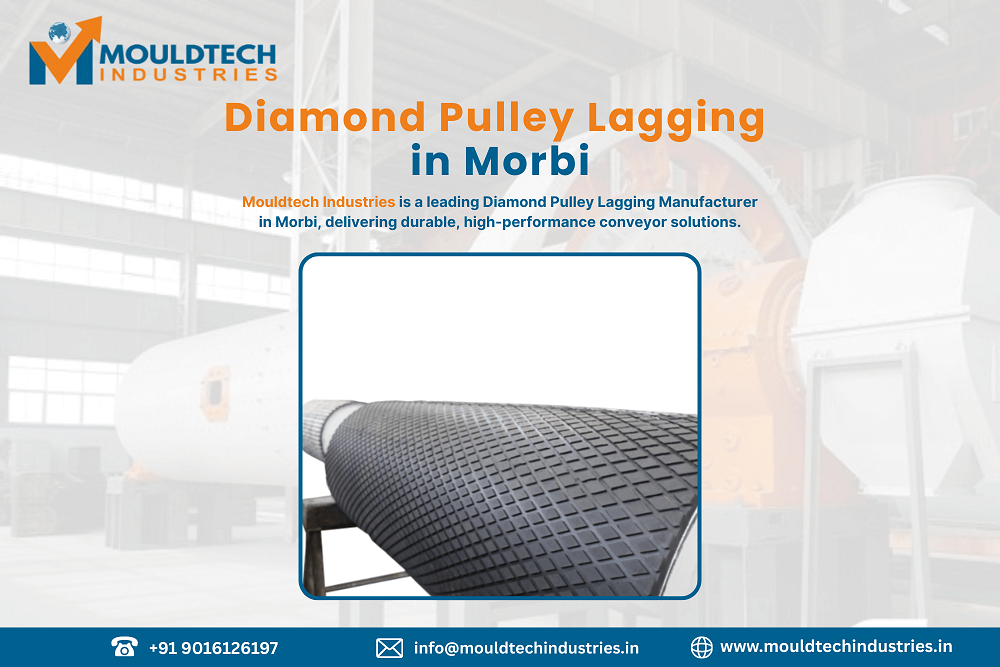

Mouldtech Industries is a Manufacturer of Ceramic Lagged Pulley in Morbi.

Our Manufacturing Unit is in Vadodara, Gujarat, India.

Mouldtech Industries is a Manufacturer of Bridge Rubber Pad, Ball Mill Rubber Lining, Bridge Rubber Pad, Resistant Rubber Liner, Embedded Rubber Liners, Conveyors Solutions, Ceramic Lagging Sheet, Belt Cleaners, Bridge Rubber Pad, Ceramic Rubber Lagging Services, and Ceramic Rubber Lagging Sheet.

Ceramic Lagged Pulleys: Wear Protection Solutions for Heavy‑Duty Industrial Operations

Industrial operations in mining, cement, metal & steel, ceramics, and bulk material handling are defined by relentless abrasion, impact loads, high throughput, and continuous duty cycles. In such environments, equipment reliability is not optional — it’s foundational to plant efficiency, safety, and cost control.

Experienced plant engineers often observe that wear‑related failures and material buildup on conveyor pulleys rank among the most critical issues affecting throughput and maintenance reliability. In heavy‑duty industrial environments, production losses frequently stem from cascading failures that begin at material transfer points.

This is where Ceramic Lagged Pulleys become a pivotal component — not merely add‑ons but engineered solutions tailored to protect rotating elements, extend service life, and stabilize materials in motion.

Industrial Challenges That Drive Demand for Ceramic Lagged Pulleys

Across mining, metal processing, cement production, ceramic manufacturing, and bulk material handling, plants face similar wear drivers that impact reliability:

- Abrasion: Bulk solids like iron ore, bauxite, clinker, and silica are extremely abrasive. When these materials contact pulley surfaces at high speed and pressure, conventional pulleys experience accelerated wear. Abrasion not only alters pulley diameter over time but also roughens surfaces, increasing friction and belt wear.

- Impact Loads: In applications where material is fed from chutes or drop points, pulleys endure dynamic impact stresses. These loads can fatigue base materials and welds, leading to structural failures if not engineered to absorb and distribute energy.

- Corrosion: In chemical, power, or mineral processing plants, pulleys may encounter corrosive atmospheres or fluid sprays. Corrosion weakens metals, undermines protective coatings, and accelerates wear.

- Downtime: Unplanned pulley replacement or maintenance disruptions lead to significant downtime — especially in continuous processes like clinker transport, ore reclaim, or kiln feed systems.

- Maintenance Cost: Frequent downtime drives repair costs, inventory stocking of spare parts, and extra labor. In global industrial environments such as those found in metal hubs (Jharkhand, Chhattisgarh), cement clusters (Rajasthan, Andhra Pradesh), and mining belts (Odisha, Karnataka), uptime directly correlates with competitiveness.

These realities underscore why engineered pulley solutions like Ceramic Lagged Pulleys are not optional accessories — they are strategic investments in uptime and equipment longevity.

What Is a Ceramic Lagged Pulley?

A Ceramic Lagged Pulley is a power transmission pulley engineered with ceramic wear protection tiles bonded or mechanically anchored to its lagging surface. Unlike traditional rubber or metal lagging, ceramic composite lagging offers:

- Exceptional wear resistance against abrasive solids

- Surface hardness to reduce material adhesion

- Improved traction with conveyor belts under challenging conditions

In industrial terms, a ceramic lagged pulley combines a robust rotating element with a high‑wear‑resistant surface engineered to survive the harsh operating environments found in heavy industries. The ceramic tiles work by presenting a stable and wear‑resistant interface between the conveyor belt and the pulley body, thereby extending service life and lowering the frequency of pulley replacement.

Applications Across Industries

Ceramic lagged pulleys find real, measurable usage across multiple sectors:

- Mining: In mines, conveyor systems transport ore, waste rock, and fines — often under heavy loads. Ceramic lagged pulleys resist abrasive wear caused by hard rock fragments and reduce belt slippage in high‑load zones, particularly at head and tail sections.

- Cement Plants: Cement production involves handling clinker, limestone, fly ash, and gypsum — all highly abrasive. Ceramic lagged pulleys at transfer points, feeders, and long‑distance conveyors help mitigate wear and buildup, supporting higher plant availability.

- Metal & Steel Plants: Steel plants move raw materials like sinter, coke, iron ore pellets, and slag. Ceramic lagging on pulleys aids in handling sharp, hard particles that would otherwise wear lagging rapidly and create surface irregularities that damage belts.

- Ceramic Manufacturing: Ceramic tile and sanitaryware factories handle abrasive powders and granulates. Here, ceramic lagged pulleys provide wear resistance and a compatible material interface that resists abrasion without contaminating processed material.

- Power Plants: Coal plants and biomass facilities deal with abrasive fuel and ash. Ceramic lagging extends the life of pulleys exposed to these materials and reduces unplanned outages due to lagging failure.

- Bulk Material Handling: From ports to distribution centers handling grain, chemicals, and aggregates, ceramics on pulley surfaces improve belt adhesion and resist wear from abrasive bulk solids.

Material Science & Engineering Considerations

To understand why ceramic lagged pulleys perform well, it’s important to examine the materials science principles behind them.

- Rubber Properties: Traditional rubber lagging provides decent traction and reduces belt wear under moderate conditions. Rubber is resilient, flexible, and forgiving to minor surface irregularities, but its wear resistance against sharp or abrasive solids is limited.

- Ceramic Hardness: Ceramics used in industrial lagging are engineered for high hardness and wear resistance. Hardness is a measure of a material’s resistance to surface penetration and abrasion. While ceramics are inherently brittle compared to metals or rubbers, when embedded and supported correctly, they offer exceptional longevity in abrasive environments.

Wear Resistance Principles

Wear resistance in industrial environments is influenced by:

- Material hardness

- Surface finish

- Load distribution

- Operating environment chemistry: Ceramics maintain smoother surfaces over time, minimizing belt drag and reducing the formation of material build‑ups that compromise pulley performance.

- Impact Absorption Engineering: Although ceramics are hard, they are not inherently impact‑resilient. That is why ceramic lagged pulley designs often integrate them within a resilient backing system, where rubber or engineered elastomers act as shock absorbers while ceramics handle abrasion.

This engineered synergy is what delivers performance without compromising structural reliability — a concept well understood by experienced OEMs and plant engineers.

Design & Customization Requirements

Ceramic lagged pulleys are not “one‑size‑fits‑all” components.

Equipment Compatibility

Every conveyor system has different:

- Belt widths

- Shaft diameters

- Pulley diameters

- Tension profiles

Design must align with existing plant mechanical layouts to avoid misalignment, vibration, and accelerated wear.

Custom Sizing

Plants may require custom ceramic tile patterns or segment sizes to match:

- Belt surface features

- Material characteristics

- Load conditions

This ensures uniform wear and avoids localized stress concentrations.

Application‑Specific Engineering

Mining conveyors vs. cement conveyors have different requirements in terms of:

- Material impact angles

- Speed of rotation

- Dust conditions

Engineering teams must assess these factors to tailor lagging design.

Manufacturing Quality & Process Control

Producing reliable ceramic lagged pulleys demands industrial manufacturing rigor:

Precision Manufacturing

Machining tolerances must ensure:

- Concentricity of the pulley

- Uniform tile placement

- Proper bonding or mechanical anchoring of ceramics

Even minor deviations can lead to imbalance, vibration, or belt misalignment.

Quality Checks

Experienced manufacturers implement:

- Non‑destructive testing

- Hardness verification of ceramic tiles

- Bond integrity tests

- Dimensional inspection

These controls prevent failures and support predictable life cycles.

Batch Consistency

In bulk production, maintaining consistency across batches ensures that components behave predictably under load, reducing variation in field performance.

Installation & Maintenance Considerations

Proper installation and maintenance are critical for realizing the full benefits of ceramic lagged pulleys.

- Ease of Installation: In industrial plants, maintenance windows are limited. Lagged pulleys designed with modular ceramic segments facilitate faster installation and replacement versus monolithic designs.

- Reduced Downtime: A well‑designed pulley with properly executed lagging reduces the frequency of replacement and the associated downtime for belt tensioning and alignment.

Maintenance Cycles

Experienced engineers plan ceramic lagged pulley deployments to align with:

- Belt replacement cycles

- Scheduled shutdowns

- Inspection intervals

This planning minimizes unplanned outages and improves life‑cycle management.

Safety & Operational Reliability

Industrial safety and reliability are inseparable.

Worker Safety

Smooth, wear‑resistant pulley surfaces reduce the risk of:

- Material spillage

- Belt slippage

- Unexpected equipment failure

These factors contribute to safer work zones around conveyors.

Equipment Protection

Ceramic lagging protects the pulley shell from wear, preventing:

- Structural weakening

- Fatigue cracks

- Premature failures

It also mitigates belt edge damage caused by rough or worn lagging surfaces.

Plant Reliability: Systems equipped with engineered wear protection consistently deliver higher uptime, better throughput, and less reactive maintenance — all hallmarks of operational reliability.

Cost Efficiency Over Equipment Life Cycle

While engineered ceramic lagged pulleys may have higher upfront cost compared to basic alternatives, experienced plant teams evaluate total cost of ownership, which includes:

Long‑Term Savings

Extended service life reduces:

- Repeat purchases

- Inventory carrying costs

- Emergency repairs

- Reduced Shutdowns

Fewer unplanned stops translate to:

- Higher production availability

- Better adherence to delivery schedules

- Lower labor costs for troubleshooting

Maintenance Optimization

With predictable wear patterns and longer intervals between repairs, maintenance crews can focus on other priorities rather than frequent lagging changes.

This lifecycle perspective is a cornerstone of disciplined operations in steel plants (West Bengal, Odisha), cement hubs (Madhya Pradesh, Tamil Nadu), and mining belts (Jharkhand, Chhattisgarh, Rajasthan).

Export Readiness & Global Acceptance

Industrial buyers worldwide have stringent expectations for wear protection components:

Documentation & Standards

Export readiness involves:

- Material certificates

- Quality assurance documentation

- Compliance with international bearing, welding, and mechanical standards

Global Buyer Requirements

Buyers in mining hubs in Australia, South Africa, Canada, and in bulk handling sectors within Southeast Asia demand verified performance, traceability, and reliable supply — all part of being export‑ready.

Manufacturers with long‑term industry exposure understand these expectations and design processes accordingly.

Why Experienced Manufacturers Matter

Engineered solutions like ceramic lagged pulleys are not commodities. Their success in a plant environment hinges on:

Engineering Expertise

Designing lagging solutions that actually extend service life without introducing new failure modes requires deep understanding of:

- Material science

- Conveyor dynamics

- Plant‑specific operating envelopes

- Industry Experience

Manufacturers who have served mining, cement, and heavy industries across Pan India and global markets understand regional production nuances and real field challenges.

Reliable Supply: Global industrial supply chains reward reliability — timely deliveries, robust packaging, accurate documentation — all support uninterrupted operations.

About Mouldtech Industries

Mouldtech Industries is a seasoned industrial manufacturer delivering engineered wear protection and conveyor solutions across Pan India and to global industrial customers. With sustained engagement in heavy industries — including mining, cement, metal & steel plants, ceramic manufacturing hubs, and bulk material handling facilities — Mouldtech’s expertise reflects practical engineering experience, quality manufacturing, and field‑proven performance.

Whether it’s ball mill rubber liners, ceramic wear protection solutions, or rubber lining systems, Mouldtech understands the operational context that drives uptime and reliability.

Conclusion

In heavy‑duty industrial environments, equipment reliability and wear protection are not theoretical concerns — they are measurable drivers of plant performance and profitability. Ceramic Lagged Pulleys provide a scientifically engineered pathway to handle abrasive, impact‑laden, and continuous duty conveyor services with improved operational stability.

By combining material science with application‑specific design, these pulleys enhance plant uptime, reduce maintenance interventions, and contribute to safer operations across mining, cement, metal, ceramic, and bulk material handling sectors.

For plant engineers and operations leaders seeking dependable conveyor performance, discussing engineered lagging options with experienced manufacturers can unlock performance gains that extend far beyond the pulley itself.

Key Takeaways

- Ceramic lagged pulleys address wear, abrasion, and impact loads in heavy industries

- Engineered surfaces improve operational reliability and belt traction

- Applications span mining, cement, metal & steel, ceramics, and bulk handling

- Material science principles underscore performance advantages

- Design, quality control, and installation are critical to long life

Trending FAQs

1. How long does a ceramic lagged pulley typically last in service?

Lifespan varies with material abrasiveness and operating conditions. In heavy, abrasive environments, ceramics can significantly outlast conventional lagging — often providing measurable life extension compared to rubber alone.

2. Are ceramic lagged pulleys suitable for all conveyor applications?

They excel in abrasive, high‑impact conveyor zones. In less demanding applications, traditional lagging may suffice, but ceramics provide added reliability where wear is severe.

3. How often should ceramic lagged pulleys be inspected?

Inspection frequency aligns with scheduled maintenance cycles — typically during major belt checks or plant shutdowns.

4. What is the difference between ceramic and rubber wear solutions?

Rubber offers flexibility and shock absorption; ceramics provide high hardness and wear resistance.

5. Are ceramic lagged pulleys used globally or only in India?

They are used globally in mining, cement, metal, and bulk handling markets, especially where abrasive materials and heavy loads are prevalent.

Contact Mouldtech Industries today for expert guidance on Ceramic Lagged Pulley, Ball Mill Rubber Liners, and Conveyor Solutions. Reach out for inquiries, quotes, or technical support.

#CeramicLaggedPulley #BallMillRubberLiner #CeramicWearProtectionTiles #RubberLiningSystems #BallMillRubberProducts #ConveyorBeltSolutions #BeltCleaners #IndustrialWearProtection #MouldtechIndustries